What is a Flying Probe Test?

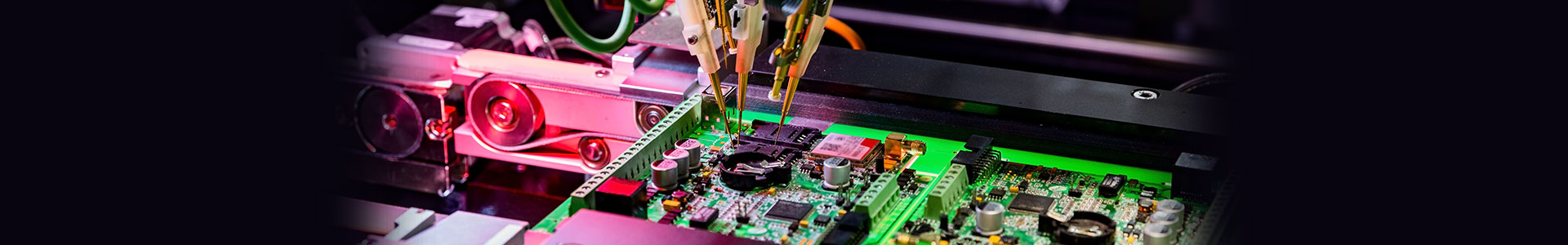

A flying probe test is an automated testing method used in printed circuit board (PCB) fabrication. It employs a small number of movable probes that simultaneously traverse the top and bottom of a PCB to check for electrical integrity. The probes follow a programmed sequence to test various points on the board, identifying shorts, opens, and other defects without requiring a custom fixture. This flexibility makes it ideal for prototype testing and low-volume production. Flying probe testing ensures quick setup, high accuracy, and comprehensive fault coverage, making it a cost-effective and efficient solution in the PCB testing process.

Flying Probe Test

A Flying Probe Test utilizes an automated system equipped with a small number of probes that traverse both the top and bottom of a PCB simultaneously. Controlled by a programmed set of instructions specific to each board, these probes move between test points to conduct comprehensive testing.

PCB flying probe testing is increasingly favored for its ability to enhance test speed, provide improved access, and offer extensive fault coverage. Unlike In-Circuit Testing (ICT), it eliminates the need for expensive test fixtures, thereby reducing costs and allowing for easier adaptation to design changes through simple adjustments to the test program. Another advantage of PCB Flying Probe Testing is its capability to perform power-up testing by injecting signals at designated points on the board and verifying outputs at others.

In scenarios where board space is at a premium, Flying Probe testing can utilize vias as embedded test points, minimizing the requirement for additional test points. This method is particularly beneficial for low-volume and prototype circuit boards, where the ease of programming and flexibility of the Flying Probe tester outweigh the cost considerations of traditional bed-of-nails ICT.

Technotronix specializes in offering comprehensive flying probe testing services as part of our printed circuit board fabrication process. Our advanced flying probe tester ensures accurate and efficient testing without the need for complex fixtures, making it an ideal choice for both prototype development and low-volume production runs.

Capabilities In Flying Probe Testing

At Technotronix, our Flying Probe PCB Test services include:

- Simple optical tests.

- Probing onto a minimum contact pad of 80 microns.

- AOI camera for presence, polarity, letter and go.

- LED functional testing with color and intensity test.

- Vector less test IC-opens.

- Extra power-up testing, where needed.

Benefits of Flying Probe Testing

- A big benefit of Flying Probe Testing in printed circuit board fabrication is its lower up-front investment compared to ICT, as no extra costs are incurred for fixtures.

- Flying Probe Testing requires minimal programming time, making it efficient for testing prototypes and low-volume production runs.

- This method ensures quick time-to-market by streamlining the testing process.

- It reduces debug time significantly by easily detecting issues such as shorts, opens, missing components, and incorrect polarities.

- Unlike other testing methods, Flying Probe Testing does not require additional efforts for Design for Manufacturing (DFM) or data messaging.

- The accuracy of Flying Probe Testing is exceptionally high, ensuring reliable results in circuit board fabrication.

- It is well-suited for testing double-sided boards efficiently and effectively.

Technotronix offers comprehensive flying probe testing services as part of our printed circuit board fabrication process. Our advanced capabilities ensure accurate and rapid testing, facilitating quick turnaround times for prototypes and low-volume production runs. With minimal upfront costs and high accuracy, Flying Probe Testing is an ideal choice for ensuring the quality and reliability of your PCBs.

Application of Flying Probe Testing

Flying probe testing is suitable to test:

- Resistance

- Capacitance

- Inductance

- Opens

- Shorts

- Diode checks, and more.

Additionally, PCB flying probe test works well for low-volume builds. It is also recommended if you are not going to order a functional test after the visual test.

How Technotronix can help you with PCB flying probe test?

At Technotronix, with over 40 years of experience in fabricating and assembling a diverse range of PCBs, we are trusted by customers across various industry verticals for delivering superior quality boards. We prioritize the use of robust testing methodologies to ensure that your PCBs are free from costly errors. Our fast turnaround flying probe tests are particularly well-suited for prototypes and low-volume production, offering efficient and reliable testing solutions.

Here's what you can expect from us:

- Expert Engineers: Our skilled engineers bring extensive experience and expertise to every project, ensuring thorough evaluation and testing of your PCBs.

- Comprehensive Test Coverage: We employ flying probe testing with extensive test coverage, ensuring all critical aspects of your PCB design are verified for functionality and reliability.

- Statistical Analysis: Utilizing advanced statistical analysis techniques, we ensure that our testing methods provide reliable data insights to optimize your PCB manufacturing process.

Our expert team collaborates closely with you to determine the most suitable testing method based on your project's specifications and order quantity. Whether you require precision testing for complex designs or rapid turnaround for prototype validation, we tailor our services to meet your needs effectively.

Partnering with us also grants you access to industry-leading best practices, giving your project a competitive advantage. We guarantee that your boards are delivered precisely according to your design files, facilitating seamless assembly and deployment.

At Technotronix, we prioritize maintaining the integrity of your boards throughout the fabrication process. Our commitment to quality extends to ensuring quick turnaround times, helping you accelerate your time-to-market goals.

Reach out to our team today to discuss your custom printed circuit board fabrication services requirements. Rest assured, you will receive a highly competitive quote and personalized service to meet your unique project needs.

FAQs

Do you have any PCB flying probe testing requirements? Request a free PCB fabrication quote. Alternatively, email BoM, Gerber files, and other required details at [email protected] or call us 714/630-9200.

PCB Assembled in 24 hours

Kitted and Turn-Key option as per customers requirement.

REQUEST OUR BROCHURE

Request Brochure

Request Brochure Please provide your email address. We’ll send you copy of our brochure in a PDF format.