What is the Electrical Testing of PCBs?

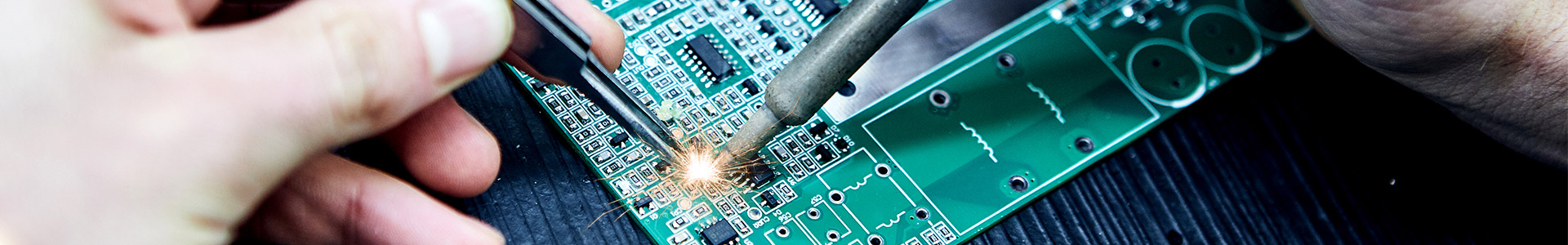

Electrical testing of PCBs is a vital process in confirming the consistency and functionality of printed circuit boards. This testing verifies that the electrical connections on the PCB are correctly established and that there are no defects such as shorts, opens, or incorrect component placements. The key methods of electrical testing contain In-Circuit Testing (ICT) and Flying Probe Testing. ICT uses a bed of nails fixture to contact various test points on the printed circuit boards, checking each component's functionality and verifying correct assembly. Flying Probe Testing, on the other hand, uses moving probes to test the electrical performance of the board without the need for a custom fixture. Electrical testing is performed after PCB fabrication and assembly to ensure that the board meets the design specifications and operates correctly in its intended application. This process is essential for maintaining the quality and reliability of the final product.

PCB Electrical Testing

When it comes to printed circuit boards, defects are never an option. PCB electrical testing is the key to achieving perfect boards every time. Especially in mission-critical operations, any downtime is unacceptable. This is precisely why electrical testing is becoming increasingly important in PCB fabrication and assembly. It ensures that the connectivity of the PCB is as specified and that there are no defects or flaws.

As PCBs become more complex with multilayered designs, miniaturization, and high-density configurations, the significance of PCB electrical testing cannot be overstated. This testing verifies that the electrical connections on the PCB are correctly established and free from issues such as shorts, opens, or incorrect component placements. By identifying and addressing these defects early in the process, manufacturers can avoid costly mistakes and ensure the reliability and performance of the final product.

At Technotronix, we offer robust printed circuit board electrical testing services that are integral to our PCB fabrication and assembly processes. Our advanced testing methods, including In-Circuit Testing (ICT) and Flying Probe Testing, ensure comprehensive verification of each board's electrical performance. ICT uses a bed of nails fixture to test each component's functionality and verify correct assembly, while Flying Probe Testing employs moving probes to test electrical performance without the need for a custom fixture.

Our commitment to quality ensures that our clients receive reliable, high-performance PCBs that meet their exact specifications. By incorporating rigorous electrical testing into our processes, we help you avoid any potential issues, ensuring that your PCBs are ready for even the most demanding applications.

Printed Circuit Board Electrical Testing Capabilities

At Technotronix, our PCB electrical testing options include:

Flying Probe / Fixtureless Testing

We make extensive use of flying probe testing, especially when volumes or product mix demands make building a fixture infeasible. Flying probe test systems have few restrictions on board access and can test boards with virtually unlimited numbers of nets. Flying probe testing also allows for testing in a short period of time. The demand for improved test speed, board access, reliability, and repeatability make flying probe testing a preferred choice in the printed circuit board fabrication process.

Bed of Nails Fixture

A bed of nails is a specific tool for fixture testing. The advantages offered by this test include high speed, accuracy, and the reusability of fixed tools. This method is highly effective in custom circuit board fabrication services, where consistent and precise testing is crucial.

Hi Potential Testing

Hi-Pot or Dielectric Withstanding testing validates the insulation between atypical plane or potential layers. Typically, the steps involved in Hi-Pot testing include:

- Application of voltage to the net.

- Holding voltage for dwell time to detect any stray current.

- Moving to the next pair.

Hi-Pot testing is an essential part of the printed circuit board fabrication process, ensuring that insulation standards are met.

4 Wire Kelvin Testing

Also known as the four-terminal resistance measurement method, 4 Wire Kelvin Testing can measure extremely small resistance in IVH and through holes. The big advantage is that it is not impacted by test lead or contact resistance, making it highly reliable for custom circuit board fabrication services.

Embedded Resistance and Capacitance Testing

With the miniaturization of printed circuit boards and the integration of embedded resistors in the PCB, embedded resistance and capacitance testing is critical. This test can accurately measure embedded resistance, ensuring that manufacturers' specifications are met. It is an important step in the printed circuit board fabrication process to maintain high-quality standards.

Benefits of PCB Electrical Testing

- Board Electrical Testing is the go-to method for multi-layered PCBs and densely populated boards with high-value components. It is essential for ensuring the reliability and functionality of complex designs in the printed circuit board fabrication process.

- A major benefit of electrical testing is that PCB designs with copper poured to cover most of the board surface are more likely to experience short circuits. Such boards significantly benefit from electrical testing, which helps in detecting and preventing these issues early.

- Another advantage of electrical testing is that the cost is a small percentage of the finished board cost, resulting in a high return on investment. This makes it an economical choice for ensuring quality in custom circuit board fabrication services.

- Electrical tests such as Flying Probe offer the flexibility of a quick setup, making them preferred for their short lead time. This is particularly beneficial for those seeking efficient PCB fabrication near me.

- Additionally, Flying Probe tests reveal not only shorts and opens but also expose design errors. This comprehensive testing capability is highly valued by any reputable PCB fabrication company aiming to deliver reliable and error-free boards.

By incorporating these advanced testing methods, we enhance the printed circuit board fabrication process, ensuring high-quality and reliable circuit board fabrication for all our clients.

Application of PCB Electrical Tests

Printed circuit board electrical testing comes in handy at the end of the PCB production process to ensure that the interconnectivity of the PCB is as per the original board data. Electrical testing therefore finds extensive application with PCBs with 2 layers or more.

In fact, as PCBs designs get more and more complex and as drilled holes continue to grow smaller, the need for electrical testing has been growing across industries.

Technotronix Advantage

At Technotronix, with over four decades of experience in printed circuit board fabrication and assembly, we specialize in delivering technologically superior PCBs across various industries. Our commitment to excellence is driven by our adoption of cutting-edge technology and extensive technical expertise.

We provide robust PCB testing methodologies to ensure flawless products that meet your requirements without costly errors post-market launch. Partnering with us grants you access to industry best practices, enhancing your competitive edge. Rest assured, your boards will be delivered precisely as per design files, allowing seamless assembly without manufacturing defects.

As PCB designs become smaller and more complex, our advanced electrical testing safeguards board integrity. We offer quick turnaround times for prototype quantities or large production runs, maintaining unwavering dedication to quality.

Contact our team today to discuss your custom requirements. Our experienced professionals will provide a tailored quote, ensuring your satisfaction with our custom circuit board fabrication services.

FAQs

Do you have any PCB electrical testing requirements? Request a free PCB fabrication quote. Alternatively, email BoM, Gerber files, and other required details at [email protected] or call us 714/630-9200.

PCB Assembled in 24 hours

Kitted and Turn-Key option as per customers requirement.

REQUEST OUR BROCHURE

Request Brochure

Request Brochure Please provide your email address. We’ll send you copy of our brochure in a PDF format.