What Is PCB Functional Testing?

PCB Functional Testing (FCT) is a vital process in the manufacturing of printed circuit boards (PCBs) intended at verifying the proper functioning of the assembled boards. This testing ensures that each PCB meets the design specifications and performs as expected in its intended application. FCT involves applying power to the PCB and running a series of tests that simulate the board's operational environment. These tests may include checking signal integrity, verifying component functionality, and ensuring proper communication between various parts of the PCB. The process helps identify defects such as short circuits, open circuits, and incorrect component placement that may have occurred during PCB fabrication. By conducting functional testing, manufacturers can guarantee the reliability and quality of their printed circuit board fabrication, reducing the risk of failures in the final product.

PCB Functional Testing

PCB Functional Testing (FCT) is the most crucial procedure to ensure zero-defect printed circuit boards (PCBs). In the world of electronics, quality and reliability are paramount. Given that PCBs are integral components of any electronic device, ensuring their thorough testing is essential. Detecting and addressing defects at the PCB stage is critical to prevent failures in the final product. FCT is designed to identify defects in circuit board assemblies, ensuring each board meets design specifications and performs as expected in its intended application. This step provides the final green light for manufacturers to proceed with shipping and delivery.

At Technotronix, we prioritize the quality of printed circuit boards, circuit board assemblies, fabrication, prototypes, and more. Our commitment to excellence is reflected in our rigorous testing protocols, including comprehensive functional testing of PCBs and PCB assemblies. By simulating the board's operational environment, we verify signal integrity, component functionality, and proper communication between various parts of the PCB. This meticulous approach helps identify potential issues such as short circuits, open circuits, and incorrect component placement that may occur during printed circuit board fabrication.

Our dedication to quality has made us a trusted partner for a range of industries seeking custom circuit board fabrication services. We understand that every application has unique requirements, and our ability to deliver tailored solutions sets us apart. From prototype development to full-scale production, our end-to-end PCB assembly services are designed to meet the highest standards of quality and reliability.

In conclusion, PCB functional testing is a vital step in ensuring the performance and reliability of electronic devices. At Technotronix, we leverage our expertise in printed circuit board fabrication and custom circuit board fabrication services to deliver top-notch products that meet our clients' exacting standards. With our rigorous testing processes, including PCB functional tests, we ensure that our PCBs are ready to perform flawlessly in any application.

PCB Functional Testing Capabilities

Functional testing, the final step in PCB manufacturing, is crucial for ensuring zero-defect printed circuit boards. Unlike In-Circuit Testing (ICT), which tests individual components after soldering, functional testing evaluates the overall functionality of the entire PCB. This approach is essential in modern electronics, especially with the trend toward miniaturization. As components become smaller and more integrated, verifying the complete functionality of the PCB becomes increasingly important. Functional testing ensures that the printed circuit board operates as intended in its final application, detecting any issues that might have been missed during earlier testing phases.

Here is a quick overview of our functional testing capabilities:

- Our team of qualified test engineers continually evaluates and develops test printed circuit boards and assemblies.

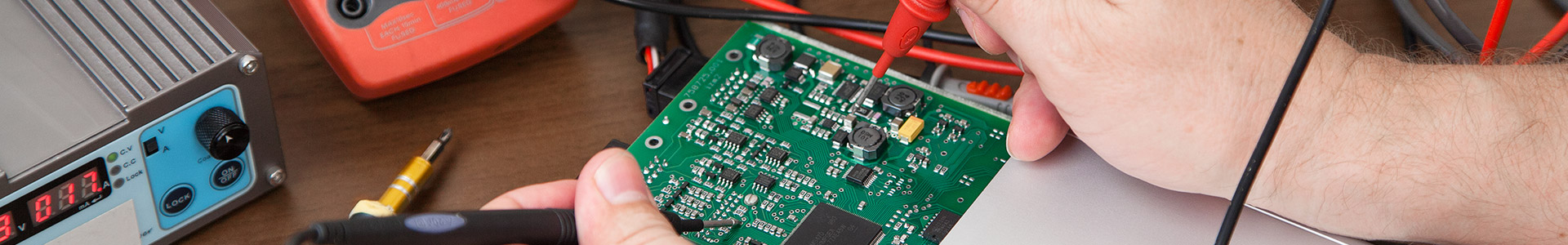

- Functional testing requires instruments such as I/O PCBs, communication ports, digital multimeters, and more.

- Typically, the testing is conducted according to procedures and specifications outlined by the test engineer.

- With the tester connected to the circuit board through a probe point, it simulates the electrical environment of the PCB.

- This process ensures that the testing is fool proof, and any flaws in design or functionality are detected, preventing costly mistakes later.

By incorporating functional testing into our printed circuit boards assembly process, we ensure that each PCB meets the highest standards of quality. This critical step in the PCB fabrication process involves using precise instruments to verify the overall functionality of the board. Our circuit board fabrication services are designed to catch any potential issues early on, ensuring reliable and high-performance products.

Benefits of PCB Functional Testing Service

There are several benefits of PCB functional testing, including but not limited to:

- Detection of any faulty or missing components.

- In case of any fault, it triggers a root cause analysis.

- Importantly, the entire process of analysis and fixing is documented. This ensures there is a laid-down guideline that helps improve quality.

- It is cost-efficient.

- It works in sync with other testing methodologies such as in-circuit testing and flying probe testing.

- It can be used to test each PCB, so there are no chances of error.

Functional testing is a critical part of the printed circuit board fabrication process. It ensures the detection and correction of issues early, saving costs and improving reliability. The comprehensive documentation of the analysis and fixing process contributes to continuous quality improvement. Additionally, functional testing complements other testing methodologies, offering a robust approach to verifying PCB functionality. By testing each PCB thoroughly, it eliminates potential errors, ensuring high-quality circuit board fabrication services.

Application of PCB Functional Testing

PCB functional testing is widely used as the final step in the PCB manufacturing process. It is the critical test that determines whether the PCB can be shipped. By validating that the hardware is free of defects, functional testing plays a crucial role in printed circuit board manufacturing and assembly. While the specific requirements and procedures for functional testing may vary, its importance in ensuring the functionality of printed circuit boards cannot be overstated. This final test confirms that the PCB performs as intended, ensuring reliability and quality before delivery. As a result, functional testing is an essential component of producing high-quality PCBs.

Ensure Printed Circuit Board Functional Testing with Technotronix

Over the last 4 decades Technotronix has emerged as a reliable end-to-end partner for your PCB fabrication and assembly requirements. No matter how complex your requirement is, you can count on our team of experts to offer you plausible solutions. What we also have on offer are industry best practices that ensure that you are not required to make costly mistakes.

The big advantage that we offer is also our quick turnaround times that ensure that you can go-to market quickly. We are well-equipped to offer both prototype quantities and large production runs, also endear us to our customers.

The fact that we have an extremely experienced and qualified team ensures that we undertake robust testing for all our PCBs. With our PCBs complying with the highest industry standards and certifications, you can rest assured that you receive cutting-edge products. Our printed circuit boards are complied with IPC standards, as well as ISO 9001:2015 and AS9100D standards.

We also offer PCB turnkey services that take away the hassle from you and offer you high quality products.

What you need to do is to simply get in touch with our team and share your requirements. We offer you a competitive quote that ensures the cost-effectiveness of your project.

FAQs

Do you have any PCB functional testing requirements? Request a free PCB fabrication quote. Alternatively, email BoM, Gerber files, and other required details at [email protected] or call us 714/630-9200.

PCB Assembled in 24 hours

Kitted and Turn-Key option as per customers requirement.

REQUEST OUR BROCHURE

Request Brochure

Request Brochure Please provide your email address. We’ll send you copy of our brochure in a PDF format.