Metal Fabrication

As a leading PCB manufacturing company, Technotronix offers a comprehensive range of metal fabrication services, leveraging the latest technology and state-of-the-art equipment. Our skilled fabricators and engineers are dedicated to providing quality solutions tailored to any design and specification. To ensure successful end designs and precision metal fabrication, we utilize a diverse array of metal materials, including aluminum, mild steel, carbon steel, stainless steel, copper, bronze, brass, and more. This versatility allows us to produce high-quality products that meet the specific needs of your project.

Our capabilities extend to custom circuit board fabrication services, where we apply our extensive expertise to create bespoke PCBs that meet your exact requirements. Whether you need printed circuit board fabrication for high-power applications, high-frequency designs, or complex multilayer boards, our team is equipped to deliver exceptional results.

In addition to our local operations, we have an offshore manufacturing facility that enhances our production capabilities. This enables us to efficiently manufacture and export a wide variety of custom metal components, turned parts, electrical components, and extrusion products based on your custom requirements, specifications, and drawings. Our global reach ensures that we can meet your demands with the highest level of quality and precision.

By choosing Technotronix, you gain access to a wealth of industry best practices and cutting-edge technology that ensure the integrity and performance of your products. We are committed to delivering cost-effective solutions that enhance your project's competitiveness in the market. Our focus on quality, reliability, and customer satisfaction makes us a trusted partner for all your metal fabrication and custom circuit board fabrication needs.

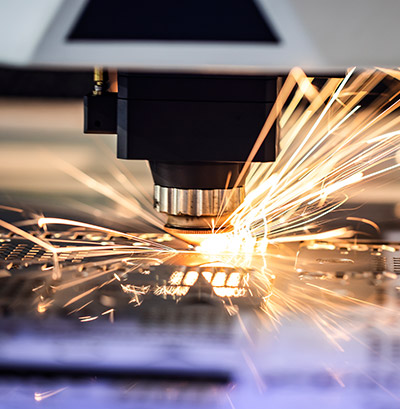

Custom Metal Fabrication

We confidently provide customized metal manufacturing solutions for a wide range of precision metal fabrication needs. Our engineers and experts offer the best fabrication solutions based on custom product samples, drawings, and specifications. From the initial design stage to product completion, we assist you every step of the way. Our metal fabricators team specializes in enhancing any custom design and specification to achieve optimum production efficiencies. Whether your product is simple or complex, we meet your exact requirements with our custom metal fabrication services, including:

- Metal Fabrication Design

- Metal Laser Cutting

- Metal Casting

- Metal Bending

- Metal Welding

- Metal Forging

- Prototyping

- Metal Hydroforming

- Metal Stamping

- Metal Punching

- Metal Shearing

- Metal Machining

- Metal Polishing

At Technotronix, we also excel in printed circuit board fabrication and PCB manufacturing. Our expertise ensures that every project, whether it involves custom metal components or custom PCBs, is completed with the highest level of precision and quality. We leverage advanced technology and state-of-the-art equipment to deliver superior results, enhancing the performance and reliability of your products.

By choosing our services, you gain access to industry best practices and cutting-edge techniques that ensure the success of your project. Our commitment to quality, efficiency, and customer satisfaction makes us a trusted partner for all your metal fabrication and printed circuit board manufacturing needs.

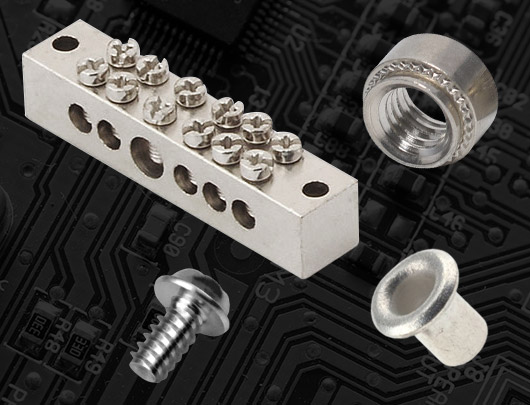

Metal Fabrication Services & Capabilities – Metal Components

Technotronix collaborates with clients to design, manufacture, and fabricate a wide range of fasteners, including screws, bolts, nuts, rivets, washers, spacers, standoffs, and more. From small individual parts to large assemblies, we offer comprehensive solutions. In addition to fasteners, we have the capability to design and build various metal components, electrical components, metal-turned parts, and more. We provide a complete turnkey metal fabrication solution.

To meet your required standards for metal fabrication, we use high-quality materials and adhere to all national and international standards for the manufacturing of parts, components, and assemblies. The most common raw materials we use include:

- Carbon Steel

- Stainless Steel

- Steel

- Aluminum

- Iron

- Brass

- Bronze

- Copper

We offer MIG or TIG welding for any weldable alloy and provide dependable metal forming services. With expert finishing and assembly, we ensure that your parts meet exact requirements and custom specifications. Our finishing options include natural finishing, painting, galvanizing, anodizing, and many other options.

Additionally, our expertise extends to custom circuit board fabrication services and PCB fabrication. We deliver high-quality PCBs that meet precise design specifications and performance requirements. By choosing Technotronix, you gain access to a comprehensive range of fabrication services and industry-leading practices, ensuring the success of your projects.

Benefits of Metal Fabrication

There are a number of benefits that come with trusting us to meet your metal components manufacturing requirements. Here are some of the main benefits:

- Highly Durable

- Extra Strong

- Heat resistance

- Aesthetic Quality

- Cost-efficiency

- Versatility in fabrication

- More flexibility

- Light final product

- Enhanced appearance

Boost Profits with Lower Manufacturing Costs

We work with you to reduce overall manufacturing costs, which results in more profits. During the design process, our engineers can help uncover weaknesses without the need for expensive prototypes. We help cut costs while delivering large production of metal components, electrical components, fasteners, turned parts and more.

Meet the International Standards for Metal Components

Customized fabricated metal components, fasteners and parts often need to comply with specific industrial compliant standards, which can vary across regions. To meet the national or international standards, work with a team that has global experience and resources. We adhere to all international standards for the fabrication and manufacturing of all types of parts, components, and assemblies.

Application of Metal Fabrication

Fabricated metal components are highly portable, malleable and withstands high pressure, all these advantages make it most suitable for any small or large industrial application. Here are some minor and major applications of metal fabrication in everyday life.

Automobile bodies

Agriculture

Aircraft

Building and Construction

Consumer Products

Manufacturing

Tools and hardware

Smartphone and laptop shells

Electronics gadgets

Medical industry

Marine

Railway

Telecommunications

You can rely on us for short-run or high-volume fabrication and manufacturing. We also provide world-class precision components, custom fasteners, parts, products and quality assurance.

An Experienced Metal Fabrication Company

We pride ourselves to offer a wide range of metal fabrication service in California. Therefore, we are capable of meeting the needs of our customers in the metal forming. Whether you are looking for fabrication service for industrial application or various PCB design, here we provide a vast range of industrial and specific fabrication solution that makes your fabrication plans a reality.

As a U.S. based leading metal fabrication company, we treat each project as if it’s our own and strive to deliver the best possible results every time. We offer,

- Offshore Metal Fabrication Services

- Custom Metal Fabrication

- Trusted & Professional Metal Fabrication Service

- Better Quality Products

- Quality Finishes

- Value added assembly services

- Packaging and Delivery

- Competitive pricing

FAQs

Some of them include:

- Powder Coating

- Silk Screening

- Anodizing

- Electroplating

- Thermal Spraying

- Dip Coat Painting

Do you have any Metal Fabrication requirements? Request a free Quote. Alternatively, email BoM, Gerber files, and other required details at [email protected] or call us 714/630-9200.

PCB Assembled in 24 hours

Kitted and Turn-Key option as per customers requirement.

REQUEST OUR BROCHURE

Request Brochure

Request Brochure Please provide your email address. We’ll send you copy of our brochure in a PDF format.