Through Hole PCB Assembly

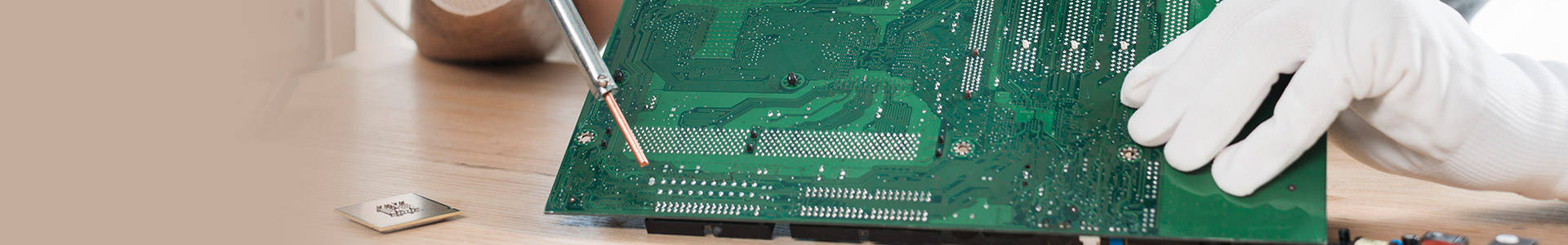

At Technotronix, we specialize in providing comprehensive through hole PCB assembly services, ensuring seamless integration from prototype development to full-scale production. Our commitment to quality is supported by state-of-the-art technology solutions that enable us to deliver exceptional results at every stage. We offer a complete range of capabilities for through hole PCB assembly, including conformal coating, PCB encapsulation, RoHS compliance, labeling, functional testing, device programming, and surface finishing, all adhering to stringent international quality standards.

Our team consists of highly trained professionals with extensive experience in both manual and automated assembly techniques. We specialize in precise hand soldering of components and efficient automated insertion processes for axial and radial components. Whether handling complex assemblies that require meticulous attention to detail or fulfilling small-volume production requirements with automated efficiency, we ensure that every project meets the highest standards of quality and reliability. Technotronix is your trusted partner for superior through hole PCB assembly services, tailored to meet your specific needs and exceed your expectations.

Our Stringent Through Hole PCB Testing Protocols Include

Thermal Profiling

- Crucial in THT assembly for optimizing temperature profiles.

- Identifies defects like insufficient solder and misaligned components, ensuring robust PCB assembly and manufacturing reliability.

Flying Probe Testing

- Valuable for through hole PCB assembly in low-volume and complex scenarios.

- Detects missing components and validates precise component placement, enhancing accuracy in PCB assembly processes.

ICT Testing (In-Circuit Testing)

- Essential in PCB manufacturing for high-volume production.

- Efficiently detects parametric failures, PCB layout-related faults, and component issues, ensuring stringent quality control in assembly.

Functional Testing

- Validates PCB operations and behavior in THT assembly.

- Detects faulty component values and ensures compliance with functional and parametric standards, optimizing PCB manufacturing reliability.

These testing methods are integral to THT assembly and PCB manufacturing, ensuring minimal production losses, enhanced employee safety, stable processes, prolonged equipment life, reduced environmental impact, and efficient spare parts inventory management.

Benefits of Through Hole PCB Assembly

Through hole PCB assembly offers distinct advantages over surface mount technology (SMT), particularly in its ability to withstand mechanical and environmental stresses more effectively. This makes it suitable for components subjected to high power and voltage requirements, ensuring reliability in demanding applications across various industries. Its resilience in handling elevated temperatures further enhances its appeal, providing stability and longevity in operational environments where heat tolerance is crucial. Moreover, through hole assembly simplifies prototyping processes due to its straightforward construction and soldering techniques, contributing to improved reliability in early-stage product development. Despite the prevalence of SMT for smaller, lighter components, through hole technology remains indispensable for larger and heavier components that demand robust connections and durability. Its enduring relevance underscores its role in modern PCB manufacturing, where reliability and performance under challenging conditions are paramount.

WHY US?

Here’s why a large portfolio of customers across industry verticals choose Technotronix for through hole PCB assembly requirements:

- Over 44 years of experience and expertise in delivering cutting edge products.

- Quick turnaround and stringent delivery schedules.

- Full and partial turnkey solutions.

- RoHS compliant assemblies.

- No minimum order quantities. You can count on us for prototypes as well as large production runs.

- Optimal costs.

FAQs

Are you in need of Through Hole PCB assembly services? Get a free quote today by submitting your requirements. Email your Bill of Materials (BoM), Gerber files, and any other necessary details to [email protected] or call us 714/630-9200.

PCB Assembled in 24 hours

Kitted and Turn-Key option as per customers requirement.

REQUEST OUR BROCHURE

Request Brochure

Request Brochure Please provide your email address. We’ll send you copy of our brochure in a PDF format.