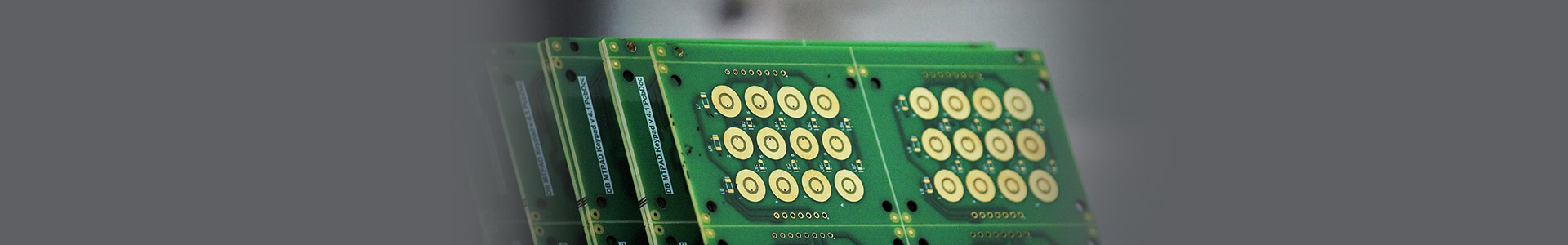

Multilayer PCB

Experience top-quality Multilayer PCBs with our advanced manufacturing capabilities and state-of-the-art facility. At TechnoTronix, we excel in crafting each board to meet your precise requirements and technical specifications. Our superior engineering ensures meticulous attention to detail throughout the multilayer PCB manufacturing process, safeguarding against the impact of heat and pressure on each layer.

Adhering to stringent multilayer printed circuit board manufacturing practices, we specialize in handling complex boards with up to 32 layers. These boards are carefully laminated to ensure effective insulation and feature precise electrical connections via strategically placed holes and blinds. This meticulous approach guarantees that our multilayer circuit boards operate seamlessly as a unified unit, tailored to serve the specific functions of your products.

We understand that each PCB serves a unique purpose, and our manufacturing services are tailored to your bespoke requirements. Whether it's adhering strictly to product specifications or implementing rigorous quality control measures, we are committed to delivering excellence in multilayer PCB fabrication.

Choose TechnoTronix for reliable multilayer printed circuit board fabrication in the California USA. Partner with us to ensure your PCB solutions meet the highest standards of quality, precision, and performance.

Capabilities of Multilayer PCB Manufacturing

| Capability | Standard |

|---|---|

| Layer Count | Multilayer PCB up to 24 & 32 Layers |

| Type |

Multilayer Rigid PCB Multilayer Flex PCB Multilayer Rigid-Flex PCB |

| Alternative Finish |

Hot Air Solder Level (HASL) Electroless Nickel / Immersion Gold (ENIG) Silver Electroless Tin Lead Tin Nickle Organic (OSP) Hard Gold (edge contact) Carbon Peelable Custom Specified Finishes are also available! |

| Our stringent testing protocols include |

Flying Probe test Functional testing for the specific design, and more. Impedance Test Solderability Test Electrical testing to ensure that there are no short circuits on the board. Thermal Shock Test Hole resistance test Automated Optical Inspection to check for aspects such as missing pads, spacing violations and more. |

Benefits Of Multilayer PCB

- Small Size and Lightweight: Multilayer PCBs offer a significant advantage due to their inherently compact and lightweight nature, making them ideal for portable applications. As miniaturization becomes increasingly important across various appliances, multilayer printed circuit boards excel in meeting these requirements.

- High Quality and Reliability: Compared to single or double-layered PCBs, multilayer PCBs demonstrate superior quality and reliability. They are built to be more durable, ensuring consistent performance over time, which is crucial for mission-critical applications.

- High Flexibility: Utilizing flexible construction techniques allows for the creation of flexible multilayer circuit boards. These are well-suited for applications requiring bending and flexing, offering versatility in design and functionality.

- Powerful Performance: Multilayer printed circuit boards boast high-density designs with multiple layers, enhancing their capacity and speed. This makes them capable of handling complex electronic circuits and high-speed data transmission effectively.

- Single Connection Point: Multilayer PCBs operate as a unified unit, requiring only a single connection point. This simplifies the design of electronic products, particularly those emphasizing miniaturization and compactness, while ensuring efficient connectivity and assembly.

Choose TechnoTronix for reliable multilayer circuit board manufacturing and printed circuit board design and fabrication. Our expertise in multilayer PCB fab ensures that your projects benefit from superior quality, durability, and performance, meeting the most demanding industry standards.

Applications Of Multilayer PCB

Multilayer PCBs find extensive application in a wide range of industries including but not limited to:

Computers

Medical Equipment

Satellite Systems

Wearable Devices

Telecommunication

Electronics

Why us?

The demand for multilayer printed circuit boards (PCBs) is steadily increasing due to their smaller size, faster speeds, enhanced power capabilities, and growing popularity in various industries. As a leading manufacturer specializing in printed circuit board fabrication and multilayer PCBs, our commitment to quality begins with rigorous checks upon receiving your Gerber files. This proactive approach allows us to promptly identify and rectify any errors, thereby preventing costly mistakes during fabrication. Our meticulous design-for-manufacturing checks ensure that the entire production process adheres to stringent quality standards.

With over 40 years of experience in fabricating a wide range of multilayer boards, including printed circuit board design and fabrication, we guarantee products that consistently meet the highest quality benchmarks. Our state-of-the-art manufacturing facility in California, equipped with advanced technology and supported by an experienced team, enables us to deliver exceptional results with precision and reliability. This dedication has earned us the trust of customers across diverse industries who rely on our PCB fab expertise.

In addition to manufacturing, we provide comprehensive end-to-end services encompassing PCB layout, fabrication, warehousing, and shipping. This integrated approach ensures that your project receives complete support and seamless execution at every stage of development.

Select TechnoTronix for your multilayer printed circuit board needs in California and beyond. Benefit from our industry-leading capabilities, commitment to quality, and extensive experience in printed circuit board design and fabrication.

FAQs

- Electroless Nickel / Immersion Gold

- Silver

- Electroless Tin Lead

- Organic (OSP)

- Hard Gold (edge contact)

- Carbon

- Peelable

Do you have any Multilayer PCB Assembly requirements? Request a free Multilayer PCB Fabrication quote. Alternatively, email BoM, Gerber files, and other required details at [email protected] or call us 714/630-9200.

PCB Assembled in 24 hours

Kitted and Turn-Key option as per customers requirement.

REQUEST OUR BROCHURE

Request Brochure

Request Brochure Please provide your email address. We’ll send you copy of our brochure in a PDF format.