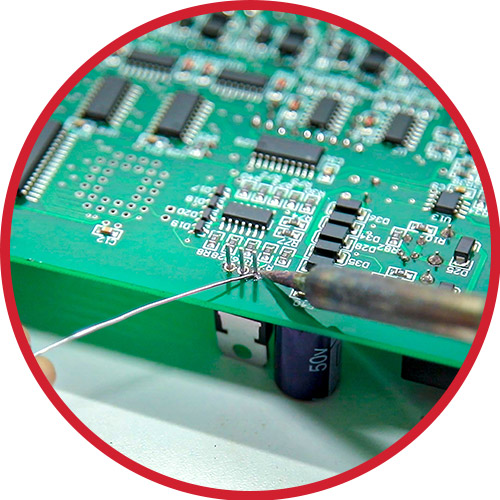

What is Surface Mount Technology?

Surface Mount Technology (SMT) is a method used to mount electronic components onto the surface of a printed circuit board (PCB). This technology utilizes small and intricate parts that are directly placed on the PCB's surface. SMT provides high mechanical strength and is widely adopted for PCB assembly due to its efficiency and space-saving benefits. In SMT PCB assembly, both the leads and components are placed on the same side of the PCB, optimizing space utilization. This versatile technology is suitable for prototyping, mass production, and PCB repair, involving the use of solder paste for secure component attachment through soldering.

SMT Assembly Service

Technotronix is a longstanding provider of surface mount PCB assembly services for customers in a range of industries. We specialize in contract manufacturing and have extensive experience with assembling electronics for a wide range of applications. With a broad selection of equipment and expert staff, we can assist with product prototyping and testing, contract manufacturing and more.

We are dedicated to manufacturing the highest quality products, whether your needs involve small or high volume SMT PCB assembly production. Through our extensive experience and continuous improvement initiatives, we ensure excellence in every project. Surface Mount Technology (SMT) is the leading and flexible assembly process used to manufacture modern, faster, and more efficient consumer electronics, telecommunications equipment, medical devices, and industrial control systems. As miniaturization becomes increasingly crucial, the significance of SMT technology continues to rise. Our surface mount PCB assembly services guarantee optimal performance and cost-effectiveness, utilizing surface mount devices (SMD) to meet industry standards and exceed customer expectations.

Capabilities Of Surface Mount PCB Assembly

- State-of-the-art SMT assembly line that ensures reliable boards.

- Production-ready components that improve turnaround.

-

Assembling single and double sided SMT PCB of the following types:

- Ball Grid Array (BGA)

- Ultra-Fine Ball Grid Array (uBGA)

- Quad Flat Pack No-Lead (QFN)

- Quad Flat Package (QFP)

- Small Outline Integrated Circuit (SOIC)

- Plastic Leaded Chip Carrier (PLCC)

- Package-On-Package (PoP)

- Small Chip Packages (Pitch of 0.2 mm)

Our stringent testing protocols for surface mount assembly include:

- Automated Optical Inspection

- X-ray testing

- In-circuit Testing

- Functional Testing

Therefore, we ensure high accuracy in high-density Surface Mount (SMT) PCB Assembly, providing top-notch SMT assembly service and serving as a reliable surface mount PCB manufacturer.

Advantages

Why us?

With over 44 years of experience, Technotronix has established itself as a reliable manufacturer of SMT printed circuit board assembly (PCB assembly). Whether you require a large-scale production run or prototypes for a new product launch, we possess the expertise and capability to meet your needs. Our state-of-the-art manufacturing facility is equipped with advanced technology to streamline the assembly process and ensure high-quality results.

At Technotronix, we prioritize customization and flexibility to accommodate diverse client requirements effectively. We tailor our approach to deliver optimal solutions, ensuring that each PCB assembly meets stringent quality standards and specifications. From initial concept to final production, our dedicated team works closely with clients to understand their unique needs and provide personalized support throughout the manufacturing process.

By partnering with Technotronix, you gain access to comprehensive PCB assembly services backed by decades of industry experience and innovation. Whether you are in telecommunications, consumer electronics, medical devices, or industrial applications, our commitment to excellence ensures that your PCB assembly needs are met with precision and reliability. Contact us today to discuss your project requirements and experience first-hand our dedication to delivering superior SMT PCB assembly solutions.

FAQs

- Automated Optical Inspection

- X-ray testing

- In-circuit Testing

- Functional Testing

- Gerber Files

- Bill of Materials

- Component Placement or Pick & Place File

Do you have any SMT assembly service requirements? Request a free SMT PCB Assembly quote. Alternatively, email BoM, Gerber files, and other required details at [email protected] or call us 714/630-9200.

PCB Assembled in 24 hours

Kitted and Turn-Key option as per customers requirement.

REQUEST OUR BROCHURE

Request Brochure

Request Brochure Please provide your email address. We’ll send you copy of our brochure in a PDF format.