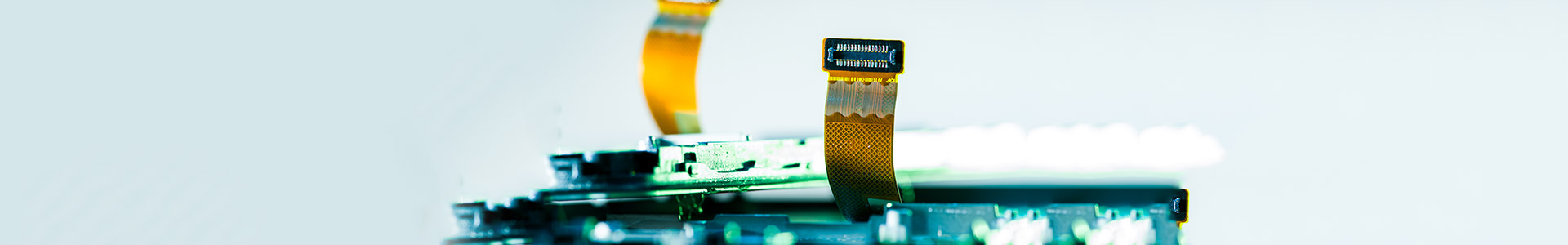

What are Rigid Flex PCBs?

Rigid-flex PCBs (rigid flex printed circuit boards) are hybrid circuit boards that integrate both rigid and flexible substrates into a single unit. These boards consist of multiple layers of flexible circuit substrates interconnected with rigid boards using plated through holes. This innovative design allows for intricate three-dimensional configurations, offering enhanced flexibility in product design while reducing the need for connectors and cables. Rigid-flex PCBs are mainly advantageous in applications where space is limited or where frequent flexing is required, such as in aerospace, medical devices, and consumer electronics. They ensure reliable electrical connections while maintaining durability and structural integrity.

Rigid Flex PCBs

Rigid flex printed circuit boards (PCBs) are an optimal solution for applications requiring ultra-thin packaging and intricate three-dimensional configurations. They seamlessly integrate elements from both rigid boards and flexible circuits, combining the structural integrity of rigid PCBs with the flexibility of flexible substrates. This innovative design allows the PCB to be folded or flexed while maintaining its shape, making it ideal for compact electronic devices where space optimization is crucial.

In the printed circuit board fabrication process, rigid flex PCBs consist of multiple layers of flexible circuit substrates interconnected with rigid boards through plated through holes. This integration not only reduces the need for connectors and cables but also enhances reliability by minimizing potential points of failure. As a leading rigid flex printed circuit board manufacturer, we specialize in providing customized solutions tailored to meet diverse industry needs including consumer appliances, industrial manufacturing, telecommunications, automotive, medical devices, renewable energy, and more.

Our PCB fabrication services ensure precise manufacturing processes that adhere to industry standards, delivering high-quality products with improved electrical performance and durability. Rigid flex PCBs streamline electronic designs, offering added functionality while maintaining structural integrity during repeated use and flexing. Whether for prototyping or large-scale production, our expertise in rigid flex circuit board fabrication caters to a wide range of applications, supporting innovation and efficiency in electronic product development.

Capabilities of Rigid Flex Circuit Boards

| Capability | Standard |

|---|---|

| Types of Rigid Flex PCB | Single Sided Rigid Flex Boards Double Sided Rigid Flex PCBs Multilayer Rigid Flex circuit boards |

| Layer Count | 2 - 24 multilayers |

| Materials | Polyimide FR4 |

| Copper Thickness | 9 µm 12 µm 18 µm 35 µm |

| Min. Line / Spacing | 125 µm / 125 µm |

| Smallest Drill | 0.28 mm |

| Surfaces | Immersion Ni/Au OSP Plated Ni/Au Immersion Tin |

| Stiffener Material | FR4 Steel Aluminum |

| Min. Annular Ring | 150 µm |

| Min. Solder mask Dam | 100 µm |

| Drill to copper – Outer layers | 8 mil |

| Drill to copper – Inner layers | 10 mil |

| Minimum Pitch | 0.5 mm |

| Copper Thickness | 0.5 oz. - 4 oz. |

| Copper to Board Edge | 0.007″ |

| Minimum Hole Size | 0.004″ |

| Coverlay Opening | 0.003″ |

Benefits of Rigid Flex PCBs

- Light weight and compact with reduced packaging size.

- Improved connection reliability with fewer solder joints.

- Fit smaller areas, contributing to large product miniaturizations.

- Known for easy assembly.

Why Us?

- We are an ISO 9001:2015 Certified PCB assembly company committed to upholding rigorous quality standards.

- With over 44 years of experience in both fabricating and assembling high-quality rigid flex printed circuit boards, we ensure precision and reliability.

- Our state-of-the-art manufacturing facilities are equipped to handle any custom and complex board requirements efficiently.

- Our highly qualified team adheres to industry best practices, offering cost-effective solutions tailored to your needs.

- Whether you need prototypes or full production runs, you can rely on our comprehensive PCB fabrication services.

- We understand the significance of quick time to market as a competitive advantage and prioritize efficiency without compromising quality.