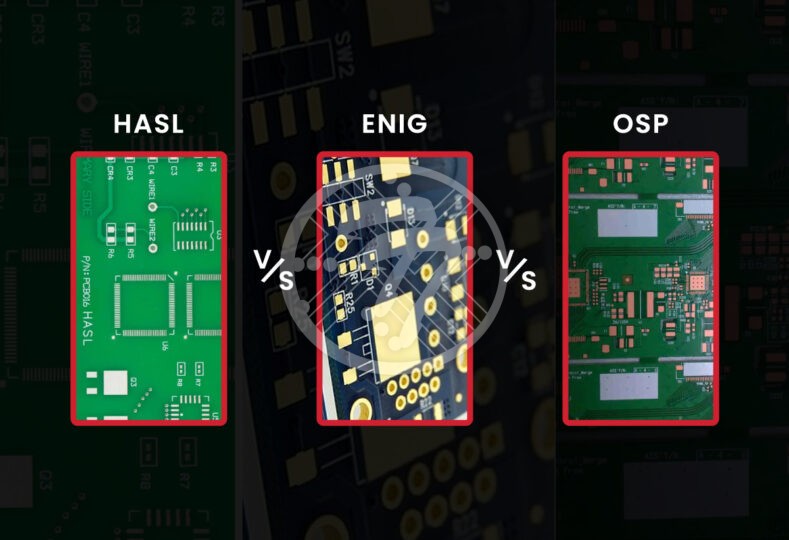

HASL vs ENIG vs OSP – What is the difference between optimal PCB surface finishes?

Choosing the right surface finish for a printed circuit board (PCB) is a vital step in achieving product reliability, solderability, and performance. Surface finishes such as HASL, ENIG, and OSP are not just protective layers – they influence electrical performance, assembly quality, environmental compliance, and even shelf life. Each finish serves a distinct purpose, making the decision especially important for industries like automotive, consumer electronics, aerospace, and medical devices.

In this blog, we break down the core differences between HASL, ENIG, and OSP surface finishes. We explore how they work, where they are best used, and what makes one better suited over the other depending on design goals and manufacturing demands.

What is HASL (Hot Air Solder Leveling)?

HASL, or Hot Air Solder Leveling, is one of the most used surface finishes in PCB manufacturing. It involves immersing the board in molten solder and then using hot air knives to remove excess solder from the surface. This creates a protective and solderable layer.

Advantages:

- Economical and widely available across board houses.

- Excellent solderability and ease of rework.

- Reasonable shelf life when stored in controlled conditions.

Disadvantages:

- Not suitable for high-density designs due to its uneven surface.

- Thermal shock during the dipping process can damage sensitive boards.

- The traditional version contains lead, making it non-compliant with RoHS standards unless a lead-free variant is used.

Typical Uses: Industrial boards, general-purpose electronics, and cost-sensitive designs that do not require very fine components.

What is ENIG (Electroless Nickel Immersion Gold)?

ENIG stands for Electroless Nickel Immersion Gold. It consists of a two-layer metallic coating where a layer of nickel is deposited chemically, followed by a thin coating of gold. The nickel acts as a barrier between the copper and gold, and the gold protects the nickel from oxidation.

Advantages:

- Provides a very flat surface, ideal for fine-pitch components like BGAs.

- Offers excellent corrosion resistance and long shelf life.

- Compliant with RoHS regulations.

- Suitable for applications requiring wire bonding.

Disadvantages:

- Higher cost compared to other finishes.

- Can be prone to a defect called black pad if not manufactured properly.

- Requires tight process control and is harder to rework than HASL.

Typical Uses: High-density PCBs, telecom, aerospace, medical devices, and applications where reliability is paramount.

What is OSP (Organic Solderability Preservative)?

OSP, or Organic Solderability Preservative, is a water-based organic compound that is applied to exposed copper pads to prevent oxidation. It is one of the most environmentally friendly and low-cost surface finish options.

Advantages:

- Very affordable and simple to apply.

- Delivers a flat surface that supports fine-pitch soldering.

- Environmentally friendly and RoHS compliant.

Disadvantages:

- Shorter shelf life compared to other finishes.

- Sensitive to handling and not suited for multiple reflow cycles.

- Provides limited protection against corrosion or mechanical wear.

Typical Uses: Consumer electronics, single-reflow assembly processes, or PCBs with a short storage timeline.

Comparision Table of HASL vs ENIG vs OSP

| Feature | HASL | ENIG | OSP |

|---|---|---|---|

| Cost | Low | High | Very low |

| Surface Flatness | Uneven | Very flat | Flat |

| Fine-Pitch Support | Poor | Excellent | Good |

| RoHS Compliance | Lead-free only | Yes | Yes |

| Shelf Life | 6–12 months | 12–18 months | 3–6 months |

| Rework ability | High | Moderate | Low |

| Corrosion Resistance | Moderate | Excellent | Low |

| Ideal Application | Industrial/Low-end | High-end/HDI | Single-use consumer |

Factors to consider when choosing a PCB surface finish

1. Design Complexity

For dense boards with small pitch components, ENIG offers the flattest and most reliable surface. HASL may introduce uneven surfaces that hinder solder joint integrity in such layouts.

2. Environmental Compliance

OSP and ENIG are both lead-free and compliant with environmental regulations. If you’re using HASL, ensure it’s the lead-free variant if compliance is required.

3. Cost Sensitivity

OSP is the most economical choice, followed by HASL. ENIG is the most expensive, but its reliability justifies the cost in complex applications.

4. Manufacturing Process Requirements

OSP is best for boards that undergo a single reflow process. For boards requiring multiple soldering cycles or long shelf life, ENIG is a better choice.

5. Mechanical Durability

ENIG is more robust and resistant to wear, making it suitable for boards that will be handled frequently or installed in rugged environments. OSP, by contrast, is delicate and should be handled carefully during assembly.

6. Storage Duration

If your product is expected to be stored for a long time before assembly, ENIG’s long shelf life makes it more reliable. OSP degrades quickly and is best suited for short manufacturing cycles.

Alternative Surface Finishes

While HASL, ENIG, and OSP are the most widely used, there are several alternative finishes:

- Immersion Silver: Offers good solderability and flatness but tarnishes easily in high humidity.

- Immersion Tin: Similar to silver but can suffer from tin whiskers over time.

- ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold): More reliable than ENIG, especially for wire bonding, but significantly more expensive.

- Hard Gold: Used in edge connectors and high-wear contact areas, not typically used for soldering.

Each of these alternatives has a specific niche but is less commonly used for general-purpose boards.

Trends and Future Outlook

As electronics become smaller and more complex, the demand for flat, reliable surface finishes continues to rise. ENIG and OSP are seeing increased adoption in high-speed and high-frequency applications. Additionally, environmental regulations are shaping surface finish selection, driving a shift away from traditional leaded HASL.

Research and development are also underway to enhance existing finishes and create hybrid solutions that combine the benefits of multiple finishes. Advances in ENEPIG, for instance, aim to offer the performance of ENIG with fewer manufacturing risks.

Conclusion

Surface finish selection is a critical decision in PCB manufacturing. Whether you choose HASL, ENIG, or OSP depends on your specific application, budget, component density, and regulatory requirements. While HASL offers affordability and ease of use, it lacks the flatness and reliability needed for more complex assemblies. ENIG delivers superior performance but comes at a higher cost. OSP is an economical and eco-friendly choice, though it requires careful handling and fast processing.

By aligning surface finish choice with the board’s purpose and assembly process, you can optimize both manufacturing efficiency and long-term performance. Always consult your PCB fabricator for recommendations tailored to your project’s unique requirements.

Looking for the right PCB surface finish for your next project? At TechnoTronix, we combine decades of PCB manufacturing and fabrication expertise with advanced capabilities to deliver the finish that best fits your application – whether it’s HASL, ENIG, or OSP. Get in touch with our team at [email protected] to discuss specific needs and receive a reliable, high-performance solution.