Conformal Coatings Becoming A Core Driver To PCB Fabrication Done For Automotive Electronics

This advanced world of innovation has made it possible for the automotive electronics come up with fresh ideas and new technologies every other day. The driver less car, EV’s, hybrid car, dual fuel vehicles and other recent buzz in automotive industry has raised the developments in miniaturization, multi feature application with tough and compact electronic solution. With this, security and safety are becoming a great sense of concern for the car manufacturers and other OEM’s. Selecting safe PCB that best suits the electronic application in the vehicle is also a difficult task for both the vehicle manufacturers and the PCB fabricator. The PCB needs proper coating to increase durability and its estimated life. Among all, the conformal coatings protect the PCB component from environmental stress.This article outlines the importance of conformal coatings and how it increases the PCB performance in the automotive electronics.

Commonplace for Automotive Coating:

Nowadays, the luxury features in a car are becoming a common requirement for the consumers. The standard features in a vehicle include rear facing cameras, automated parking system, lane departure warning system, driver assistance system and many more. While the high tech vehicle software for navigation, communication, networking, music and other technology are becoming commonplace.

More and more electronics are used in new vehicles that calls for attention to security and safety solution for electronics. The cars of current times have an inbuilt system for air bag control, automatic transmission, fuel injection system, power doors and windows, suspension control and engine control modules. This has made the researchers and investigators to focus not only on the vehicle software but also on the high quality tough hardware as well. This is now becoming a great challenge for the OEM’s and the car makers to decide a perfect PCB to be used in manufacturing that can provide a protective vehicle electronics in the next Gen innovations.

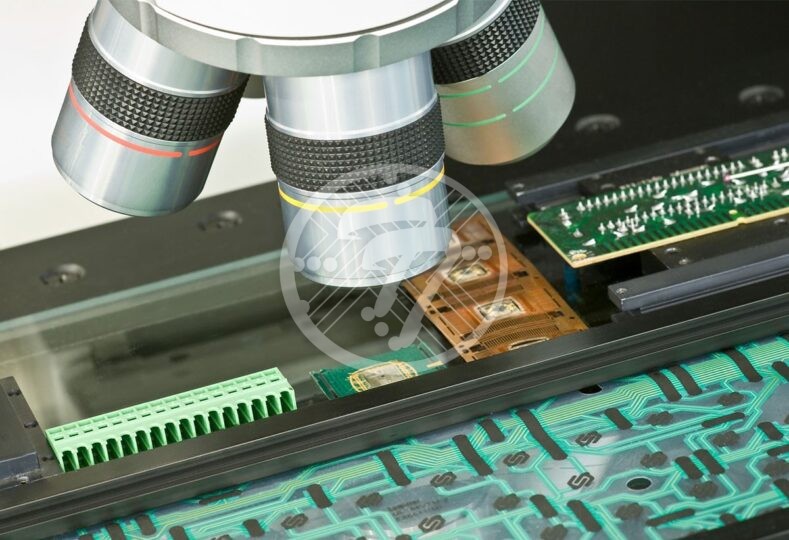

Importance of Circuit Board Conformal Coating:

The engineers have now come up with different solutions to protect the PCB for automotive applications. After considering various options like placing the circuit board in an enclosure or circuit board can be plotted with a resin, the best way to get safe PCB assembly and design is to use a conformal coating. For this, lets first dig into the meaning of conformal coatings.

The polymers applied in a thin layer of the circuit board to electrically insulate PCB components and protect it from the environmental stress are Conformal Coatings. These types of coatings are best for the compact PCB’s as they occupy less space. There are many ways to apply a conformal coating to the printed circuit board. Dispensing by a robot, spraying, flow coated or brushing are methods to apply such type of coat depending on the kind of production, be it on a massive, low or medium level production level. This safety coating can also improve PCB performance and increase the level of durability as it protects the circuit board from the humidity, thermal and mechanical stress, contaminants and corrosives that include fungi, salt, noxious gases and dirt.

Moreover, most of the lead-free printed circuit board assembly for automotive projects, notes ‘tin whiskers’ a common challenge that spurs the growth by thermal and mechanical stress leading to short circuits. The pace of this growth can be reduced by preventing short circuits and arcing through conformal coatings in the PCB. Adding more to the benefits of Circuit Board Conformal Coating, it improves the fatigue life of the solder joints with increased mechanical support.

The printed circuit boards are placed wherever they fit perfect for the car control system. From brake fluids to the gasoline fumes to the internal combustion engine, the PCB’s needs right type of coating without affecting the vehicle manufacturing process. PCB with conformal coatings are a main driver to secure electronic solution in the automotive realm.

These conformal coatings are available in a wide range depending on the type of PCB and its use. Urethane Acrylates, Silicones, Solvent based formulas and two part epoxies are the safe chemistries of coatings. While the light curable coatings also have their own advantages to provide a protective PCB solution for automotive electronics. Well, choosing correct coatings for PCB manufacturing needs proper consultation of PCB manufacturers and PCB expert. They can give a proper guide on selecting a protective coating for the PCB to be used in car and other automotive electronics. They perform qualification and environmental tests to simulate the conditions to which the particular coating will best suit for a particular application. These investigations include testing the temperature extremities, abrasion, moisture, vibration, chemicals, salt spray and other hazards.

Technotronix is a skilled and experienced professional in providing secured automotive electronics and PCB fabrication service. Our strong team of researchers and technical experts has made it possible to provide an effective lamination solution for your PCB project. Be it high frequency laminates, shrinking hole to hole pitch, exotic vias structures, multiple lamination cycle, lead free or halogen free solder assembly with strict environmental security considerations and high operating temperature are some of the highlights to our tough laminate technology implementation. You can drop an email to [email protected] or give us a call at 714/630-9200 to solve your queries or to get a quote.