How does PCB Inspection play an important role in PCB assembly process?

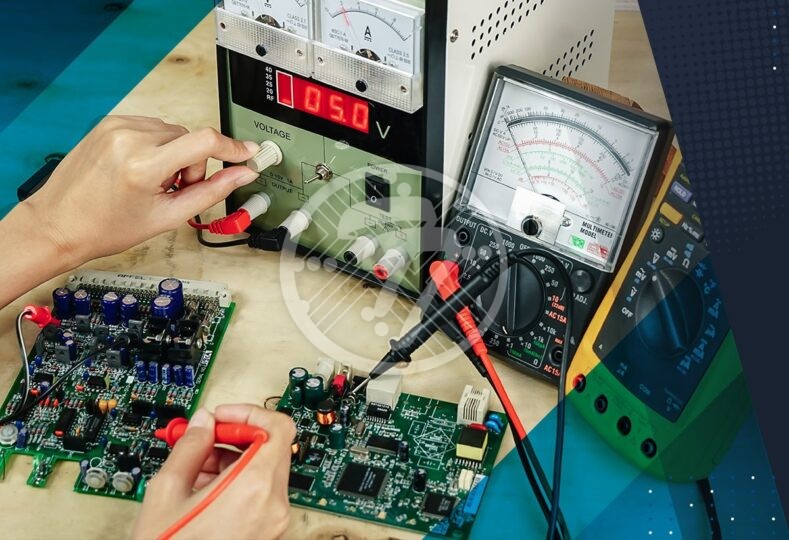

The printed circuit board assembly process isn’t complete until a robust inspection process is concluded. Its ability to point out hidden defects cannot be overstated. That it saves you precious time and protects you from costly errors at a later date is a given.

Here are some of the common PCB inspection processes that are often undertaken:

- Manual PCB inspection: As the name implies, it involves manually looking at assemblies to inspect them for problems.

- AOI PCB inspection: Automatic or automated optical inspection involves using an optical system that takes an image of the PCB assembly and to identify any flaws.

- AXI PCB inspection: With density of PCBs increasing not all solder joints may be visible. Optical inspection therefore may not serve the purpose. In such cases an X-Ray system – AXI, is able to look under the chips to view the solder joints.

- X-Ray Inspection: X-ray inspection is ideal for more complex boards & provides capabilities that other inspection methods can’t. The X-ray inspection will let you see inside solder joints to reveal bubbles that you can’t see using AOI.

Let us look at some defects that can be easily pointed out using some of these PCB inspection techniques:

Blind or Buried Vias

The use of vias in PCBs has become ubiquitous as they help different layers of the board to be connected easily. The integrity of blind and buried vias, however, cannot be ascertained with visual inspections. X-ray inspection can though send radiations that can penetrate through hidden spots and make it easy to assess the quality of connections as well as components.

Errors in landing patterns

Landing patterns of specific elements on the board often have errors associated with them. For example, if the components used on the board are not included in the library of commonly used SMD components, the chances of having the landing pattern wrong are that much higher.

BGAs

With the use of the Ball Grid Array system, components are packed with high density on the board. In this case also a PCB X-ray machine comes in handy to check the quality of components as well as board connections. The images generated from the PCB X-Rays can go a long way in seeing individual components and identify any flaws.

Decoupling Capacitors

Decoupling Capacitors help in ensuring stability of power supply as also removing oscillations and transients. Wrong placement of capacitors can however lead to suboptimal performance of the device. An inspection process ensures easy identification of any erroneous placement and correction.

Solder Voids

Soldering plays a very important role in connecting the component to the board. Any error in soldering leads to faulty connections and will impact the integrity of the PCB.

Inspection is therefore imperative to look for solder voids that can lead to low quality connections. In turn, it ensures that poor quality connections can be avoided.

Pin-Hole Fills

Through-hole is an important technique of connecting components to the PCB. However, it is prone to several defects including pin-hole fills. Essentially, they occur on account of escaping of gas while soldering. If the heat of soldering is excessive, it will lead to continuous escape of gas. During a quality assessment the pin-hole fills can be identified and integrity of soldering, ascertained.

To Sum Up

PCB Inspection comes with a wide range of benefits and ensures quality control of PCB. In fact, inspection of PCBs can help improve the overall PCB production process. If a particular defect tends to occur repeatedly, you can correct the flaw at the process level itself. Looked at in this manner, PCB inspection plays an important role in the continuous improvement of the PCB production process.

While it may be tempting to look at it like a cost, the fact remains that the cost of failure of products can be far higher, in the absence of inspection. Inspecting PCBs can uncover any defects. In fact, checking PCBs after each phase can help uncover flaws before moving to the next stage. The inspection method can help you ensure consistent quality across boards. Without a proper inspection protocol in place, flawed boards could reach the market. Especially if the defects are found out after the products have been shipped out, you not only may need to deal with expensive recalls, you will also have to face a costly loss in reputation. Worse still, a defective PCB can lead to injury or death, particularly if it is being used in a medical device or an automotive component.

From manual visual inspection to Automated Optical Inspection, X-Ray inspection, PCB functional testing and more, the wide range of inspection techniques ensure adequate performance while maintaining acceptable cycle times. Determining the best techniques for the needs of your project can go a long way in ensuring PCB integrity.

At Technotronix, we are fully equipped to handle your PCB manufacturing requirements. Our team of experts and state-of-the-art equipment ensures that all our PCBs meet the industry standards of quality and testing. It is our vast portfolio of satisfied clients that stand as the biggest testimony to our success. In case if you have any questions, please feel free to contact us via email at [email protected] or call us on 714/630-9200.