How Technology Is Rolling Up Its Sleeves for PCB Fabrication Approaches On RF and Microwave Performance?

Changing the trend of the way we do business today with high application of right communication tool that is an exact fit for your business purpose has now become one of the success mantra for every business verticals. With new models launching every other day in smartphones, tablets, laptops and other communication gadgets, the printed circuit board industry have taken a step ahead to deliver optimum electronic and design solution to suffice the requirements of manufacturing process for modified communication tools making it pretty easy for manufacturers to come up with new technology innovations. With this, the microwave and radio frequency printed circuit boards have become preeminent part of manufacturing major electronic equipment. This article will lay down insights into the technicalities of microwave PCB or radio frequency printed circuit boards with considering new PCB fabrication approaches to get an exact electronic and design solution that can get the high pace of signal speed in electronic instruments.

The new era of modernization in communication equipment and tools used in the day to day business process has marked a high scope of expansion in development for all dominant industries. With the use of Radio frequency and Microwave PCB, the PCB experts and fabricators came up with a completely new range of innovation in the global market. The microwave PCB’s have become a niche domain of expertise to grab and locate the exact needs of the electronic manufacturers. Also the Radio frequency PCB is one of the tough electronic designs that has high stability when the amplitude, current levels and voltage vary as per the climate.

Lets first dig into details of RF and microwave PCB!

The term microwave circuit is derived from a Greek word ‘micros’ which means little or small. In the microwave or radio frequency circuits, the wavelength is small in comparison to the physical variation in an electric circuit and variation in the component size that accounts for high speed in signals. It has laminates that have mechanical, electrical and thermal characteristics that are not found in FR4 materials. This type of PCB was introduced in the market in the 20th century. With this, many new microwave circuit methods were an output of research and development which included microwave integrated circuit (MIC), waveguide and coaxial technology, monolithic microwave integrated circuit (MMIC) and many more.

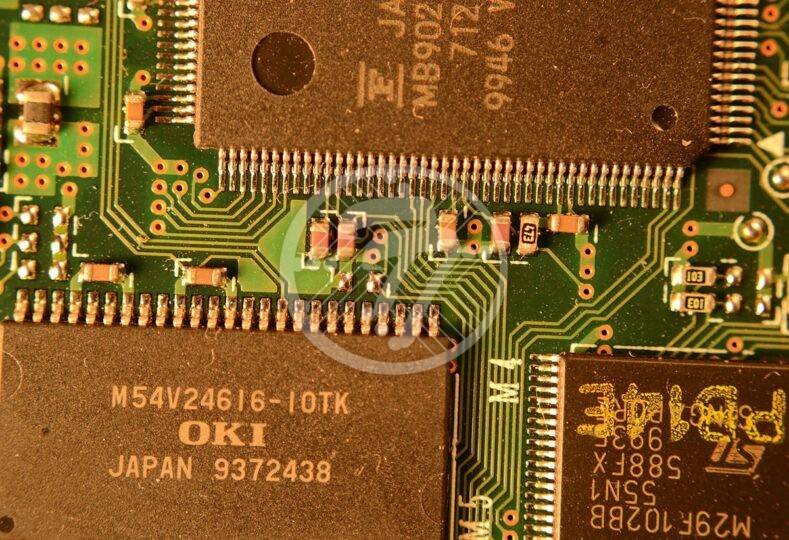

The printed circuit boards that are used in avionics and wireless circuit applications that control operations on medium to high frequency modes majorly used in communication signals are known as radio frequency PCB or microwave PCB. The Radio frequency circuits has its application to specific feature rich pcb layout that is best installed right from military radars to laptops, cell phones and many more.

The difference between normal printed circuit board and microwave PCB:

The main difference between the two is physical and electrical properties of dielectric slab. Normally the radio frequency range is 500 MHz – 2 GHz. In case of layouts above 100 MHz are considered RF PCB and that above 2 GHz will be considered microwave frequency range.

How the signal speed works out well with high performance microwave PCB?

- The important PCB fabrication approaches to make the devices have high performance output should be considered by PCB fabricators to provide best modifications with custom features in microwave PCB or RF printed circuit boards. Check out the top design guidelines for RF and Microwave PCB Assembly! The materials used in PCB manufacturing should be elements with specific attributes for dielectric constant (ER), Coefficient of Thermal Expansion (CET) and loss tangent. These make it possible for signals to speed up in traveling through the PCB with low rate of impedance. It even makes the printed circuit board to have high stability with resistance to extreme temperature climate in addition to exact placement of fine pitch components.

- Multilayered PCB is majorly used for such types of PCB applications.

- Low impedance ground plane works out well in RF and microwave PCB.

- To avoid cross talk, the RF signal lines should be placed at equal distance and quite far from each other.

- The thermal management proves best with copper shapes and planes.

- Having a solid ground plane to minimize inductance.

Other vital considerations involve the type of microwave packaging techniques that are majorly two types (ie) circuit card assemblies and hybrids. To get bulletproof reliability, Hybrid Module of packaging is proven effective which also has high application in military and aerospace industry. Whereas the circuit card assembly is best when shop for cost effective and quality solution. Furthermore, it is essential to uncover more insights into the basics of radio frequency and microwave PCB before commencing with the PCB project.

There are many other important aspects to be considered for PCB fabrication of Radio frequency or microwave PCB. To commence with any type of PCB project, be it a fresh assignment or a PCB rework, it is significant to get a consultation from a PCB expert to control costs and time with keeping quality at the forefront of your PCB project.

TechnoTronix offers Radio frequency PCB with high frequency laminates with up-graded technology used in PCB engineering to come up with the high performance RF PCB or Microwave PCB. Quality and good team of experts are key success factors of our business. This has made it possible to also build a great rapport with clients from varied business verticals and provide great tech support with quick turnarounds. Check out our PCB Fabrication Services. You can connect with us anytime to inquire about any kind of electronic manufacturing and Layout solution. Get a Quick Quote for PCB Fabrication!