What is the Importance of Thermal Pads in Circuit Board Manufacturing?

With the increased miniaturization of devices, the one thing that PCB manufacturers need to contend with is the generation of heat. Thermal management, therefore, becomes an important aspect especially since elevated temperatures make it difficult for the PCB to achieve its target performance and reliability levels.

Thermal Analysis

It is imperative that a detailed thermal analysis be undertaken. Simply put, thermal analysis refers to the process of establishing the thermal module of components and set simulation control parameters according to the structure as well as a raw material of the PCBs, package type of components as well as the operating environment of the PCB. A thorough thermal analysis undertaken in the concept phase will ensure that the exact values of component temperature, board temperature and airflow temperature are obtained, and effective heat dissipation techniques are therefore employed.

Good PCB Design Practice

Some of the PCB design and prototyping techniques that come in handy when it comes to thermal management include:

- Use of Heat sinks

- Use of thermal pads and thermal paste.

- Use of solid filled vias

- Using board material that has good thermal properties

- Cooling fans placed strategically

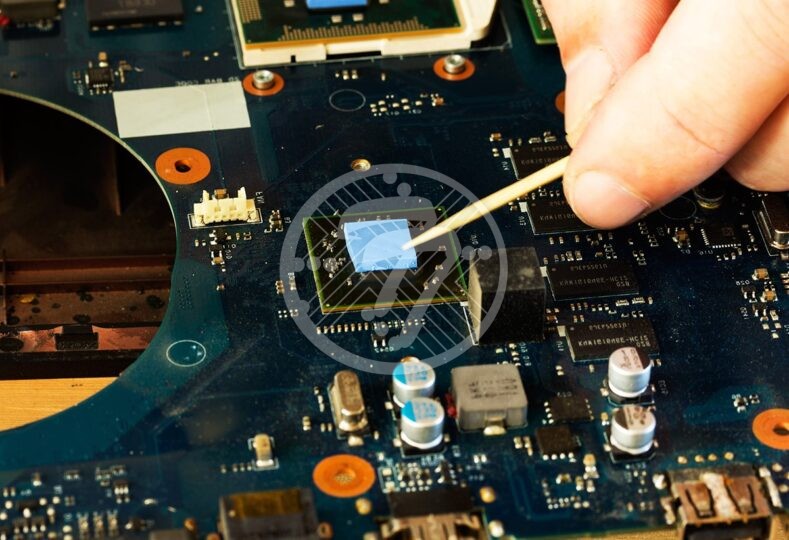

While a heat sink is a preferred device that helps dissipate the heat, however, to ensure better connectivity between the IC and the heat sink, thermal pads and thermal pastes are used.

Let us look a little closely at these two heat-dissipating components.

What are thermal pads and thermal paste?

Thermal pad

Simply put, a thermal pad is a large metal area on which a heat sink can be bolted. Thermal pads made up of thermally conductive material. When placed between the components and the heat sink, they help to dissipate heat easily.

The advantages of using thermal pads include:

- They can be deployed easily

- The material can be cut to the bespoke size required

- They are available in a wide range of materials

However, they can turn out to be expensive. Also, cutting and fitting the material will need effort and time.

Thermal paste

In essence, the thermal paste performs the same function as a thermal pad. The principle that it works on is that it closes any air gaps between the heat generating components and the heat sink. This ensures that the air gaps do not act as thermal insulators and the heat is dissipated easily. There are a wide variety of factors that influence the choice of thermal paste. Some of the factors that go into the selection include:

- Thermal Conductivity

- Viscosity

- Pump-out resiliency

- Dry-out resiliency

The advantages of using thermal paste includes:

- It is inexpensive.

- Its application is fairly easy.

- It is more durable as compared to a thermal pad as also sturdier.

However, the application of the paste can be a messy affair. Also, the thermal paste does not have as much strength as a thermal pad.

What works better – thermal pad or thermal paste?

There really isn’t a one-size-fits-all answer to that. The choice of one versus the other is really dependent on the application and the bespoke needs of the board. In certain application the use of both is prudent. Typically thermal paste is preferred where:

- The PCB has high component density

- The PCB has power components

- The PCB thermal profile shows thermal hotspots

What is a thermal relief pad?

While discussing heat dissipation techniques, it will also be prudent to touch upon the subject of thermal relief. Essentially, it is a technique used by PCB manufacturer that involves thermally separating solder pads from large copper areas so that excessive heat transfer does not occur from the pads during the soldering process that could result in a delay in melting of the soldering alloy. While its advantages from the Circuit Board Manufacturing standpoint are known, there are concerns regarding the under-utilization of heat transfer capability of large copper areas. In turn, this might lead to localized thermal hot spots at component terminals.

To sum up

To sum up, thermal management of the PCB involves several aspects including but not limited to:

- Design of power planes

- Trace Routing

- Via Placement

- Thermal Relief Pads and more

Experienced designers can go a long way in ensuring an efficient PCB design that ensures efficient thermal management.

Technotronix is one of the leading PCB (Printed Circuit Boards) manufacturers in the USA. We have over 4 decades of experience in providing innovative PCB manufacturing services using modern technologies and the latest machinery. We are adhering to strict high-quality standards and compliant with the RoHS (Restrictions of Hazardous Substance) directives. We can fulfil the varied needs of our customers from the simple board to the most complex board for PCB prototype to production.

Get a quick PCB manufacturing quote!