What is Via in PCB design? Everything you need to know about it!

With the growth of miniaturization in appliances, PCBs continue to become smaller and use fewer through-hole components. With space being constrained, surface mount technology becomes increasingly popular and the majority of through holes on most modern PCB designs end up being vias.

What is a via?

Essentially a via offers a conductive path for the electric signal to go from one circuit layer to another. A via is a plated through hole in a PCB that can be used to route a trace from the board’s surface to the inner and outer layers. Vias are essential in multilayer boards as they create the routes for flow of current between the various layers.

Types of PCB Vias

While vias perform the same broad function, there are different types of vias as well as different options for the final appearance of the vias on the PCB surface.

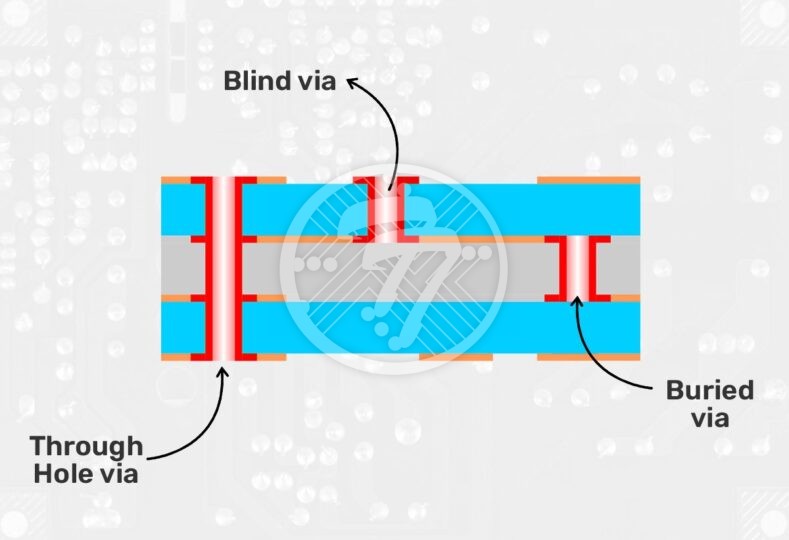

PCB Via Structures – Through, Blind, Buried

Through Vias

This is a hole that is drilled from the top to the bottom layer. It is open at both ends to allow for plating solution to flow through. In fact, through vias are the commonest and most used. All you need to do is to follow the fabricator’s rules for minimum diameter, maximum aspect ratio and adjacency.

Blind Vias

Mechanically drilled blind vias are drilled from the top or the bottom layer but do not travel the full distance through the PCB. Unlike a through via, a blind via is open only at one end, so the plating solution cannot flow all the way through the hole. In going for blind vias, it is best to go with large holes, small aspect rations and aggressive plating agitation so that air bubbles aren’t trapped at the bottom of the holes.

Buried Vias

These are used to connect internal layer structures. Sometimes they connect only internal layer pairs before being laminated.

Laser microvias

These are the smallest vias, usually around 0.003″ – 0.004″ in diameter. The big advantage with microvias is that they can fit onto tight land areas often as vias-in-pads. The pads are planarized to their original condition after plating. The pad surfaces are restored so that they can be used for component soldering. With laser microvias, the maximum aspect ratio is usually 1:1. It is therefore practical to connect 2 adjacent layers with a thin dielectric sheet. If the design is extremely dense, they can be stacked one over the other.

How are PCB vias covered or filled?

Very often additional treatment is required for the vias to improve performance and yield. Some of these methods include:

- Epoxy Hole Filling

- Secondary Solder Masking

These additional processes eliminate assembly issues that can lead to costly troubleshooting & rework.

In fact, an appropriate via treatment can help mitigate many of these issues. Let us look at some of them in detail:

Tented Vias

These vias have a non-conductive solder mask that covers the pad at both ends. Tenting via in PCB fabrication became popular when dry film solder mask was greatly used, and it could tent even relatively large holes. Today, the use of dry film masks is extremely limited. The old form of tenting, therefore, is impractical.

Encroached Vias

These have a solder mask over most of the pad but end before the hole by a few thousandths of an inch. The solder mask increases the distance between the via and the solderable pad. Also with the hole being open, there is no likelihood of any air pocket formation or contaminant entrapment.

Button Print & Plugged Vias

Essentially these are variations of filled vias. They go a long way in helping with solder flow-through. It ensures that during assembly you have the correct amount of solder on the pad. It is recommended that the PCB material used for these processes is a non-conductive epoxy hole fill. The vias need to be limited to 0.020” maximum diameter so that the hole is filled effectively.

Active Pads

They plug the hole as well as the plates over the plug. Also known as via-in-pad, it is required where the pad through which the via was originally drilled is to be used later for soldering the surface mounted component. It is also useful where you need to cool a hot-running component by drawing heat through the via. With heat drawn to the opposite side of the board, it can dissipate easily.

It is important to know that via-in-pad hosts small pitch sizes and minimizes your board’s general size. This technique works well for BGA footprint parts.

How to figure out the correct via requirements for your PCB?

The kind of via that you choose has a lot to do with the size and the functionality of your board. For example, if the board is to be used in a large computing device, the PCB design will need to conform to older standards. Possibly, a PCB with through-hole components will work best in such a situation. A PCB, for a smaller device, on the other hand, will not benefit from through hole components. In this case, you will need to make the best use of the small amount of space available. In small boards, therefore, blind micro vias will work best. Such blind micro vias can send strong signals between short distances. While small PCBs with micro vias will entail a high investment especially in terms of labor costs, however the investment will well be worth it, especially since the path breaking device could turn out to be a bestseller.

How to state your PCB via requirements?

It is imperative that your via requirements be stated clearly in the fabrication documentation. In fact, separate files for each set of vias used in the design are highly recommended. In addition, the following information needs to be provided to the fabricator:

- Type of Via- Is it through, blind or buried?

- What is the via diameter?

- The tolerances

- Layer pairs to be connected by each drill file, if blind or buried.

In terms of treatment too, you need to give the fabricator the specific details such as whether you want the plug vias partially or 100% filled. Information such as using non-conductive epoxy, applying surface finishing over the pad and more, should be painstakingly detailed. In fact, the more specific you are the better results you will get. If on the other hand, there is lack of clarity in your fabrication notes, you could face issues such as:

- Delay in receiving quotes.

- Impact on bare PCB delivery.

- Complication in the assembly cycle.

In fact, with miniaturization of appliances and the prevalence of high-density designs, it is becoming exceedingly important to clearly detail the via type as well as the treatment you require. It is also important to check that your data files are accurate and match with the requirements. In fact, time that is spent on detailing the requirements correctly will go a long way in ensuring there are no costly errors at a later date.

To sum up

Vias are becoming increasingly important on account of the following:

- In multi layered boards they help with establishing component density.

- They raise trace density in multi-layered PCBs. They allow various traces to link with each other. In such cases they act as vertical connection factors.

- They help in facilitating the transmission of signals between layers. Without the use of vias the PCB components need to be routed on a single plane.

We have more than 4 decades of experience in PCB manufacturing in USA. At Technotronix, we have the technology and production facility to offer the tenting of PCB vias with the highest degree of accuracy. With our experienced engineers you can rest assured that what you will get is an effective production. Our ability to deliver, unparalleled quality as well as customer service, is what makes us stand out. Both on-time delivery and price competitive products are our USP. The most important element of our success, however, has been the relationships we have developed with our customers.

In case you have any questions, please feel free to contact us via email at [email protected] or call us on 714/630-9200.