Basics To Drilling And How Precise Drilling Can Reduce The Cost Of PCB Fabrication?

With the speeding up of innovations in high performance electronic devices and equipments, the growth of electronic industry has taken a step ahead in development across the globe. Electronic innovations are rolling out magic, be it automobile, military, aerospace, defense, marine, telecommunication and many other sectors. One of the bases and prime product used in the electronic gadgets is the High Density Interconnection (HDI) build up printed circuit boards. These PCB has an electrical conduction between the wrings on every layer which is controlled by internal layer vias. This is where the drilling plays a crucial role in pcb layout and manufacturing. This article is a guide to the basics of drilling holes on the circuit board. It highlights the current trends in drilling technologies. The blog also updates you with how drilling can help reduce the costs?

A few decades back, PCB drilling was done with a simple drill press. The drilling operator had to move the panel manually to adjust and correct x and y coordinate and tug the lever to drill which was a time consuming operation. With the technology advancement, becoming a constant affair in the electronic market, new drilling technologies are introduced which can now, suffice a PCB to have more than 10000 drilled holes of different size. Let’s dive more into the drilling operations in pcb layout and PCB fabrication.

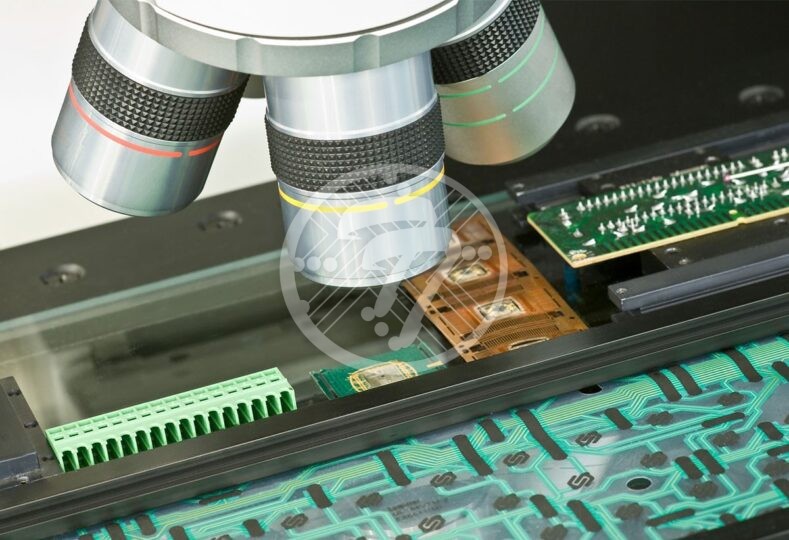

PCB Drilling

When holes are drilled typically on a board base to thermally and electrically connect the board layers is known as drilling on a circuit board. These holes when connects the board layers is called vias. The main purpose of performing a drilling operation in the PCB fabrication process is to insert a through hole component lead or to connect the board layers for developing smooth circuitry on the PCB. This becomes a crucial part of the project from the very start that includes deciding on pcb layout, the materials to be used, method to fabricate the PCB and the type of vias needed to connect the board layers. Taking one wrong step can prove to be a costly affair as one tear or mar on the trace can make a show flop ending up with more use of the material and defect in the batch of production. Check out the guide to know more about Multilayer PCB Fabrication Process.

PCB Drilling machines and drilling technologies

This drilling process is made easy with the innovations in technologies over the years. Now PCB drilling can be done with small diameter drill bits, automated drilling machine, CNC drilling machine and many other effective drilling machineries that can suit with the PCB manufacturing of multiple type of circuit boards.

Automated drilling machine can drill the holes in the circuit board by controlling the drilling operations with a computer. When many holes need to be drilled of different sizes and diameter, CNC machine is one of the effective solution saving time and cost of production.

In case of drilling registration holes to make sure that further drilling performed on the center of the internal layer pads will be precise, an x-ray drill is used. This technology is used when via holes are linking copper layers together and holes are drilled on the leaded components.

In case of vias with very small diameter, using mechanical drill bits caused increasing of breakage on the circuit board in turn increasing the cost. So researchers have come up with a laser drilling technology to get a precise solution for drilling minute holes without breakage on the circuit board. When very small holes are drilled in, the board and connected with the board layers, they are termed as micro vias. One of the extensively used drilling technology in current times is CO2 laser drilling, which is used for drilling and processing internal layer via holes.

In case of holes to be drilled for connecting only some copper layers instead of passing through the whole circuit board, one can go for a controlled depth drilling or performing pre-drilling on the sheets individually before PCB lamination or laser drilling mechanism.

It is recommended to take the help of PCB drilling experts at the initial stage of the PCB project while deciding on the pcb layout and technique of production in PCB manufacturing.

How can precise drilling help reduce the cost?

The cost of drilling well be lower when the phase of drilling operation is performed at an optimum speed. In drilling the holes in the circuit board, every operation should go hand in hand. By drilling the holes faster, the speed should also be controlled to ensure the issues of tool breakage is not a problem. This controls the drill size to board thickness ratio. With this, by controlling the time consumed for pcb layout, cost can automatically be under control.

Thus, with the efforts to reduce cost, the research and development is also heading towards getting smooth conductivity between vias and have an effective component mounting with ensuring each drill has been successfully got registered and finished the tool path.

The tool room has well developed and upgraded technologies with a team of experts that adds value to our services in turn providing quick turnarounds and effective operations in PCB fabrication. Check out our PCB fabrication services. You can drop an email to [email protected] or give us a call at 714/630-9200 to solve your queries or to get a quote.