How To Avoid Common Problems With Gerber File During PCB Manufacturing Process

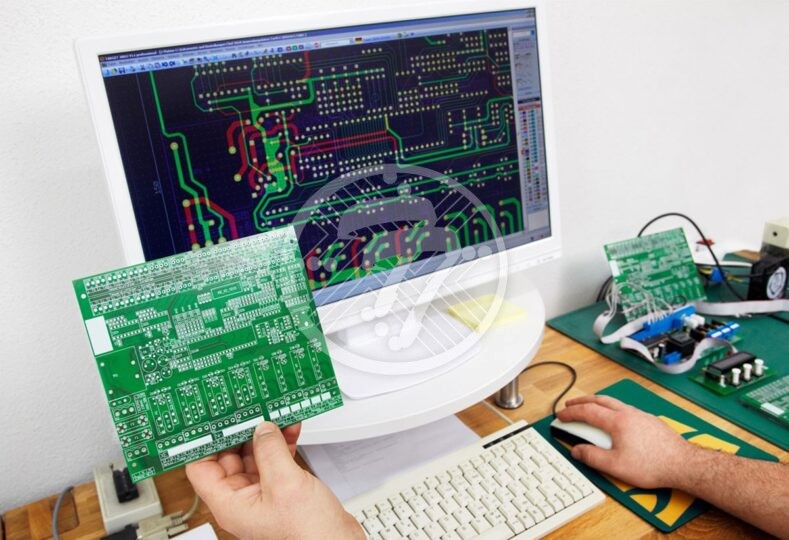

Printed Circuit boards vary in size and composition depending on their application. From basic PCBs used in standard applications to highly complex PCB configurations used in advanced applications, PCB designers are under constant pressure to design highly innovative yet efficient and functional PCB’s that can get the job done faster, better and easier. Leading edge applications like satellite guidance systems or even advanced automation systems require even more innovative PCB solutions to keep up with technological evolution in other controls. But irrespective of whether the pcb layout is simple or complex, the design phase typically ends with a series of Gerber files that serve as input for PCB manufacturer during the manufacturing and fabrication process. Gerber files can be defined as PCB blueprints in digital format used in the layer by layer manufacturing and fabrication of Printed Circuit Boards. A big part of the quality process in the manufacturing of Printed Circuit Board’s involves ensuring the Gerber files are exact and complete. Incorrect or incomplete Gerber files can result in the manufacture of faulty or non-performing PCB’s. There are multiple Gerber files that get generated for every Printed circuit board and ensuring that each one of them is not only complete but accurate as well is critical in ensuring the end product is able to perform as per specifications.

There are many errors that can occur during the creation of Gerber files, some of the more common ones include:

Missing or incomplete Gerber files

Not all Gerber files created for the same PCB are equal in size and specifications. For instance an Excellon Gerber drill file contains specifications regarding the location and size of the holes, plated and unplated to be drilled in each PCB layer. Each Excellon Gerber file needs to be complete along with the ASCII code and the tool number to be use for hole drilling for that particular layer. A single missing detail can change the entire configuration of the PCB by changing the size, shape or location of the hole on the board, which is why it is important to ensure that there are no incomplete or missing Gerber files.

Missing Aperture List

The basic purpose of an aperture list is to provide details regarding the kind and location of the tool to be used at each stage of the PCB manufacturing and fabrication process. When multiple aperture lists are generated for each layer or when the aperture list is generated in a format different from the Gerber files, the possibility for errors increase. Having a single detailed aperture list containing specifications for all the layers and in the same format as the Gerber files reduces the chances of errors and malfunctioning.

Zero byte Gerber PCB files

Sometimes design errors can lead to the creation of zero byte Gerber files that contain no information that can be used for PCB manufacturing and fabrication. It is important to check the validity of the Gerber file before sending it across to PCB manufacturers.

Incomplete or misleading Gerber file labelling

Each Gerber file needs to follow a standard naming convention that makes it easy for the manufacturer to understand its intended use. An incomplete or non-standard file labeling can create interpretation issues for the manufacturer leading to production errors and delays.

Insufficient inner clearance

Inner clearance can be defined as the minimum clearance required between the drill hole and the interconnected, adjacent inner layer copper on the printed circuit board. If the inner clearance is not sufficient, it can cause short circuit in the inner copper layer during the drilling process.

Errors in Making Composite layers

Some design software’s use compositing of layers while creating design specifications for individual layers. This can include layers with both positive and negative images and while compositing can help speed up the process it can also cause errors especially if the images are not combined properly to create a single Gerber file for each layer.

Gerber file errors can prove to be a costly and time consuming, not to mention completely avoidable. Ensure your PCB Making, manufacturing and fabrication process remains error free depends a lot on ensuring Gerber files are accurate and complete, which is possible by practicing the following steps

- When it comes to ensuring error free operations, there is nothing like establishing best practices at every step of the design and manufacturing process. This includes checking the Gerber files for completeness, correctness and length as well as validity.

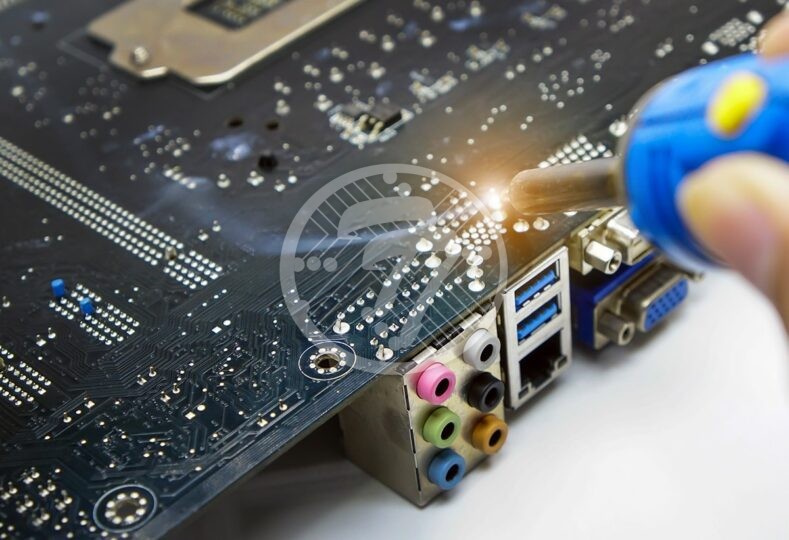

- Use a Gerber file viewer to check the Gerber files for accuracy and validity. A Gerber file viewer allows designers to validate the size of the final actual PCB and even print a sample board to check for size.

- Use advanced CAD software during the design process that are less prone to errors, some high definition CAD software are even able to provide designers with a basic design analysis before creating the actual Gerber files to be sent to PCB manufacturers and fabricators.

Adhering to these practices along with rigorous quality checks at every stage of the design process can ensure that the PCB’s manufactured by you are both high performing as well as long lasting.

Technotronix is one of the leading provider of PCB manufacturing services to all the dominant industries. Having a strong manufacturing unit with a strong tool room and a team of experts, we are the one that provides cost effective solutions with keeping quality at the nucleus in each stage of PCB manufacturing. To get proper consultation or share your requirements to get a perfect PCB with cost effective strategy or to get a quote, drop an email to sales@technotronix.us or give a call 714/630-9200!