PCB Assembly Bringing New Alters In The Renewable Industry

One of the buzz topics in the technology markets galore for everyone both in the workplace and at home is ‘Eco Friendly Practices’. Going green has now become a fire fighting requirement to grow with the communities across the US and Europe that are now heading towards increased echo conscious in new technology launches. Major echo initiatives have gradually become a taproot strategy for marketing, especially in the renewable industry. A recent kick that triggered the gamut of technology businesses is to make the climate crises go down the drain with giving a ray of light to the tree huggers, ecologist, conservationist and environmentalist. This article brings a spotlight to current trends in the market, how PCB is used in renewable energy, upcoming technologies, its application with a glance at future of renewable industry. With this, new and fresh innovations are coming up in printed circuit boards to give an echo twist to the chic products specially for the OEM’s to help them transform into green business.

Enshrining green efforts are going mainstream for manufacturing PCB for renewable technology in addition to the PCB for the wind industry, solar energy, energy management system, rain energy, power generation and agriculture industry. The fashion for environmental protection is clear and renewable are the player. For this, PCB manufacturers in the USA are taking extra steps in offering customized complete turnkey, consigned and contract manufacturing services to cast and model the echo-friendly ideas into perfect PCB prototypes.

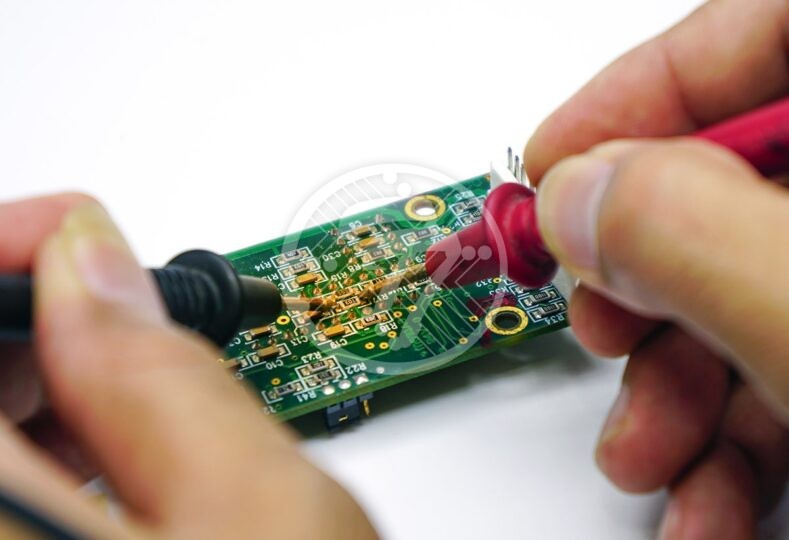

The use of heavy copper PCB in Invertors with solar and wind power storage/generation, HDI and multi layered PCB for energy management devices and equipment, rigid/flex PCB, SMT and many more has an extensive application in the renewable industry. The PCB assembly, PCB fabrication and prototyping has shown great modifications in the techniques used in the PCB production process to well maintain the quality and durability with zero defect batches of production. These new ideas will predictably change the ways people use energy.

Eco Friendly PCB Innovation:

Innovation in power generation

Leveraging the recent concepts with creative innovation in the basic PV system used for power generation has made it possible to increase the operational efficiency and durability with flexible axis solar tracker that can be connected to 50 electronic equipments. Hydroelectric generation also saw a perfect blend of implications to provoke inventions in power generation. A recent breakthrough is found in the inverters and controllers that are used in wind turbines and photovoltaic solar systems with upgrading the MPPT (Maximum Power Point Tracking) technique. Other green initiatives adopted that are even proved fruitful for data analysis of renewable energy includes Automatic Metering Infrastructure (AMI), Synchrophasor technology, micro- grid and many more techniques.

Eco Friendly PCB Innovation in agriculture industry

The grid integration of renewable energy sources in the electronic systems has marked a decent growth in agriculture sector indirectly enriching the F&B industry. The wireless based system is also making the agriculture industry to survive with the cut throat competition in the market. The control systems and electronic equipment played a vital role with need of development in agronomy, forestry and horticulture.

Eco Friendly PCB uses in other industries:

The developments are also addressed in the Renewable Energy Desilation plants to curb the droughts and water shortage problems. This up-gradation in technology has also made it possible to measure the effect of climate change in water. Apart from Water Desilation, the solar energy and renewable energy have hit the innovations in construction business one of which is seen in controlling and monitoring the building with the Building Automation System (BAS) also know as Building Management System (BMS) which maintains balance in the operation of ventilators, security system, power, fire system and lightning of the whole building. The Design Energy Management and Optimization System is used to design a hybrid PV system that allows dynamic power management with operating simulations.

Creation of underground reservoirs that are used for power generation also has implications of Geothermal energy in the US. The geothermal energy is also used in the heat pumps during winter as a heater and in summer as a cooler.

Thus, with the sensitive concern of environmental protection as a prime focus IRENA (International Renewable Energy Agency) is heading towards doubling the consumption of Renewable Energy by 2030. This will help the new start ups, manufacturing units and OEMs with a cost effective echo friendly and design savvy electronic solutions that will lead them to growth every other day.

To know more about renewable PCB, visit http://www.technotronix.us/renewable-energies.html & add para at last: At Technotronix, we are fully equipped to handle your PCB manufacturing requirements. With over 4 decades of experience in PCB manufacturing as well as assembling PCBs with differing levels of complexities, we follow industry best practices to ensure we deliver cutting-edge products. Our team of experts and state-of-the-art equipment ensures that all our PCBs meet the industry standards of quality and testing. It is our vast portfolio of satisfied clients that stand as the biggest testimony to our success. In case if you have any questions, please feel free to contact us via email at sales@technotronix.us