Prototype Circuit Boards with Surface Mount Components or Device

When manufacturing product, designing its prototype is very important. A prototype is a copy of the product being developed that gives a fair idea about how the device or product works or how it will look like. Engineers use prototype circuit boards for prototyping the electronic device. These circuit boards have small holes in which the electronic elements are fixed to get the required design. It is a common practice that many electronic engineers use prototype circuit boards with a surface mount component or device, but the question is: is it feasible? Let us delve into that.

What are surface mount devices, and how they are used with prototype circuit boards?

Surface mount technology is the prime method through which prototyping is done for electronic devices. The surface mount technology (SMT) is placed above the printed circuit board. Prototype Printed Circuit Boards Manufacturer use SMT technology only for making prototypes. The components are assembled in one place, and they are placed on the printed circuit board through the Solder-reflow process.

Specifications to be looked upon while making a Prototype Printed Circuit Boards with a surface mount component device?

Some things are required that has to be checked or looked upon while you are building a Printed circuit board-

1. Dimension

You must choose the right dimensions for your PCB. The measurements should be exactly that should take no extra space because the extra things left out are only waste material and can’t be used further.

2. Layers

It is good if the PCB has more layers, because more layers offer a better roadway to the electrical components making it more complex and unique.

3. Material

The best material for PCBs is copper, as there are a lot of benefits of using Heavy Copper in PCB Fabrication. Other than that, PEEK, Teflon, and Polyamide can also be used. The printed circuit board is typically made of glass- epoxy.

4. Board thickness

The more thickness the PCB has, the better it is, allowing a faster and inexpensive experience. The maximum thickness that is accurate is 1.5 mm.

5. Plating

Plating is an important component while designing a PCB when assembly and plating are done to cover the surface with another metallic material so that soldering can be improved.

6. Impedance control

This feature can become a problem for PCBs that have radios. The performance of the wireless antenna gets maximized if the impedance is controlled.

7. Minimum spacing and width

The PCB manufacturer decides the spacing and width. When we talk about the spacing, it refers to the copper width in the PCB.

8. Hole sizes

Big holes always remain a big no-no as they occupy more space and are very complex. Small holes are always preferred as it becomes easy to make electrical connections through it, and also, less space is needed.

9. Solder mask

The polymer is applied above the copper tracing to prevent any short circuits as the polymer is an insulator. The polymer acts as a solder mask.

10. Silkscreen

In silkscreen, graphics and texts are added to your printed circuit board.

Advantages of Prototype SMT Circuit Boards

- By using SMT technology, the size of the prototype will remain the same, just like the original piece. If the size is the same, you will get a better idea of the original product by looking at the prototype made with SMT technology.

- The minute and tiny size of SMT Assembly allows better flexibility because of the holes present. Also, the chances of parasitic attacks are less in these cases.

- This technology makes it easier to interchange the resistors and capacitors to try distinct values.

- This technology is cost-effective and a time saver.

- It gives fast results so that the product can be launched quickly in the market.

- The costs for modification of tools is also lower.

Process of assembly of Prototype SMT Circuit Boards

The assembly process of Prototype SMT Printed Circuit Boards is divided into three stages-

First stage

- In the first stage, keep the printed circuit board on a rough surface, place the stencil above the PCB from the right side.

- Keep on adjusting it till the perfect alignment is achieved.

- Put solder paste on it.

- Once the paste settles on it, detach the stencil carefully. Make sure there is no smudging.

Second stage

- Place the other elements but make sure that you use the right parts and the orientation is also correct.

- Ensure that the solder paste doesn’t get dried up completely.

- Keep the PCB in the reflow oven and make sure it gets heater properly.

Third stage

- After taking the PCB out of the oven, clean the PCB with a cleaning solution such as Isopropyl alcohol. Brush it properly.

- Connect the PCB to power so that testing can be done beforehand.

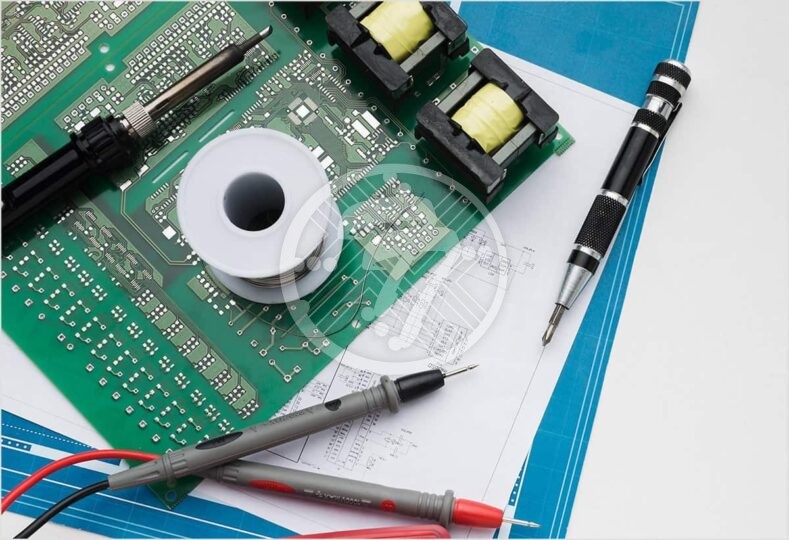

Guidelines for Surface Mount Assembly & Prototyping

- A stencil that is unframed is always preferred as it comes at an affordable price. The framed stencils are comparatively expensive and difficult to deliver.

- Make sure that you handle the PCB with care because it is very delicate when it is made.

- Make sure you use superior quality lead paste for pasting.

- When you check the PCB working, make sure it passes the test 100%, else it won’t be passed forward.

Probable mistakes that can happen

- Design is the incorrect or wrong layout.

- sufficient attention is not given to the design’s testing, especially its probe points (access points).

- The elements or components are not used properly in the prototype according to the design.

- The parts that were used were not of superior quality.

These are important things for any Circuit Boards Prototyping to have with the use of surface mount devices. This is why we need prototype circuit boards with surface mount devices. The assembly process is quite simple: follow the steps carefully and don’t commit probable mistakes.

At Technotronix with our advanced engineering to deliver unparalleled quality and PCB Prototype services. With quick Printed Circuit Boards Prototyping and consistent delivery of high-quality PCBs, we offer a robust source of competitive advantage to our clients. With our four decades of experience, you can rest assured that we are cognizant of the industry best practices and will keep you ahead of the curve. We are providing high quality and defect free PCB Prototype as per customer specification. Get a Quick Quote for Prototype Circuit Boards.