Snowballing need of the fabrication and build out of medical PCB prototypes

Over the past decade, there has been a healthy demand of PCB prototypes, especially for highly contingent medical gadgets. The USB to get reliability and repeatability in the pcb layout and PCB Manufacturing process is transparency, integrity and authenticity. This has been a major challenge in providing the electronic solutions, especially in the medical industry.

The prototypes to be applied in high tech medical apparatus, machines, equipment and accessories are mainly for dosimeter product assembly, stock and supply control devices in hospitals, a remote transmitter and receiver used for eye checkups, body movement tracking gadget, blood sugar and blood pressure monitoring, digital cell counting device, ultrasonic device, laser therapy, heart pacemaker surveying etc. The upcoming trend of high health consciousness among the people and quick transmissions due to new innovations has been a ray to leap the PCB fabrication to the next level.

One of the recent trends of using FDM technology (Fused Deposition Modeling) to create 3D printed parts marks multitude uses in medical industry. The prime use of 3D printing is for research, development, simulation and medical gadget designs. Also a growing development is found in medical supply chain transparency with application of medical electronics.

TechnoTronix has an inbuilt fabric mechanism for serving highly advanced custom PCB’s to its customers from the medical industry by providing electronic solutions to pacemakers, defibrillators, neuron stimulation, modulation devices and hearing aids.

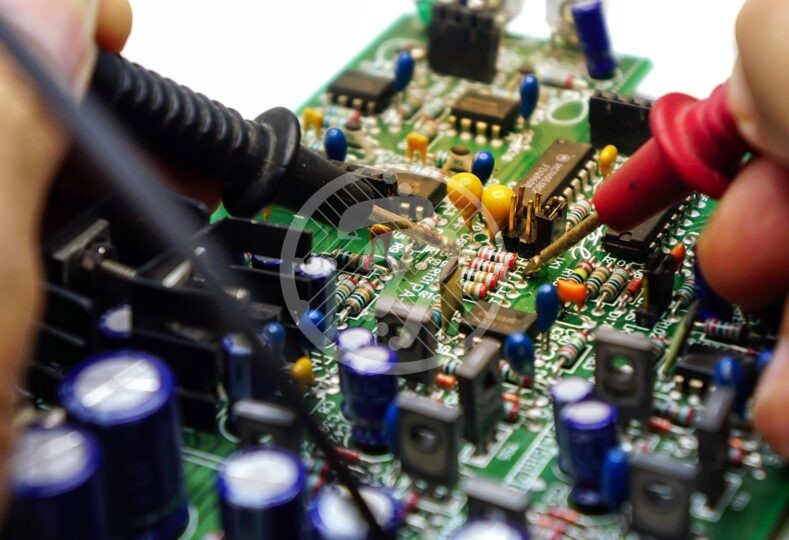

One of the chief critic requirements of manufacturing medical PCB Prototype for medical products is to have a clean signal by decreasing the ground noise in the PCB for exact diagnostics and encountering the diseases. From motor controllers, lab equipment electronics, health monitoring devices to robotic braces, we have hands on experience in tendering to the customized requirements of our clients from medical market.

As for using medical equipments- quality is a foremost necessarily, we have adopted many pre inspection techniques like solder paste inspection, thermal profiling, flying probe testing, ICT testing and functional testing to authenticate the operations and behavior of the prototype before its dispatch by maintaining international standards of quality control. Thus, with a growth in strides of medical industry, there is a mark of great need for PCB prototypes across the globe.

At Technotronix, we combine state-of-the-art technology with our advanced engineering to deliver unparalleled quality and service. We offer a robust source of competitive advantage to our clients. With our four decades of experience, you can rest assured that we are cognizant of the industry’s best practices and will keep you ahead of the curve. Visit to know more about PCB prototyping service and feel free to contact us. Also, you can drop an email to us at sales@technotronix.us.