Innovation Ploughing Into The Automotive Industry With The Help Of PCB Manufacturing

The Types of Automotive Printed Circuit Boards:

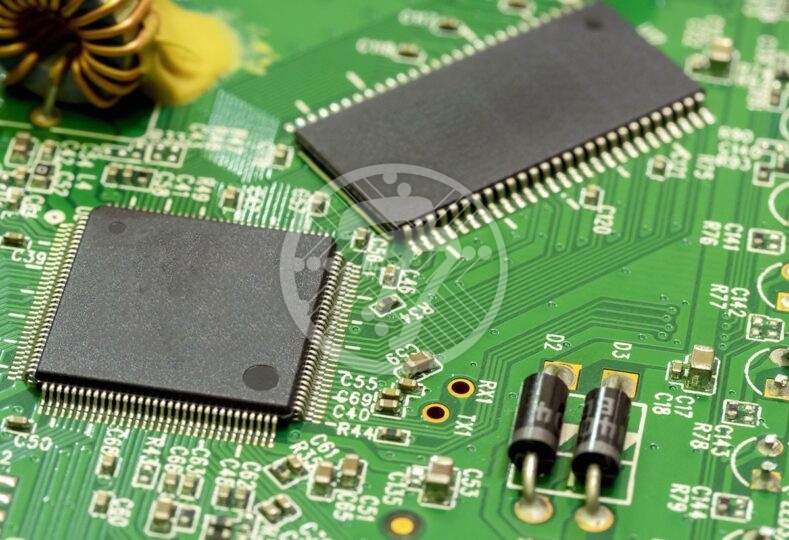

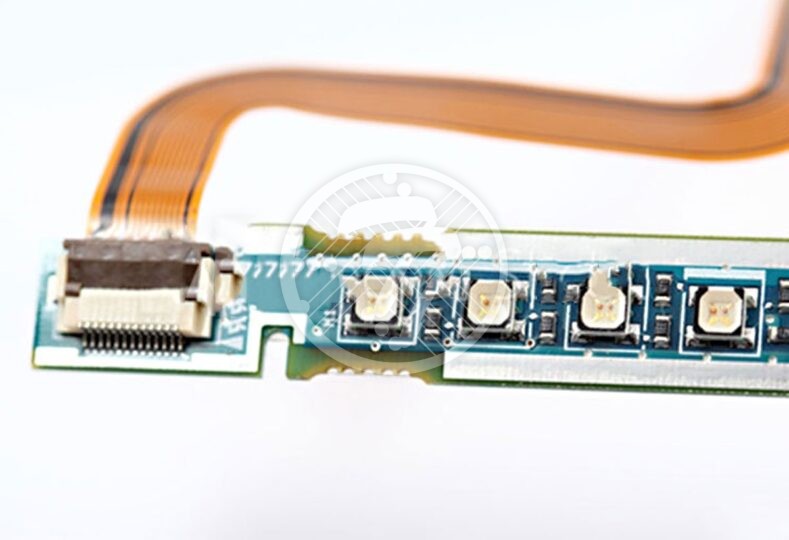

Most of the automotive innovation, car and truck manufacturing needs highly durable, reliable and tough PCB application. A high tech PCB requirement is marked that can withstand harsh driving conditions and can be a catalyst to the new innovation exposing the automotive electronics. The high power copper plated PCB is the most widely used PCB by the automakers. Furthermore, the automotive PCB prototype and PCB automotive sensors are the prime source of electronic development, especially for the Engine Management System (EMS), Dashboard, fuel regulator, power supplies and for V2V communication. The flexible PCB and other automotive electronic circuits are a prime time trend for the installation of highly compact and multi feature technology applications in vehicles. Also for unique electronic solution, PCB box Build and Cable harness PCB assembly are in hot demand. In case of limited PCB editions, PCB prototypes with cost effective techniques of production is in the mainstream to shop for innovation for most of the automotive researchers. The other technology advancement in the current times is as under with the vibe of development in PCB assembly and PCB fabrication. Check out the guide on PCB Fabrication for Automotive Electronics.

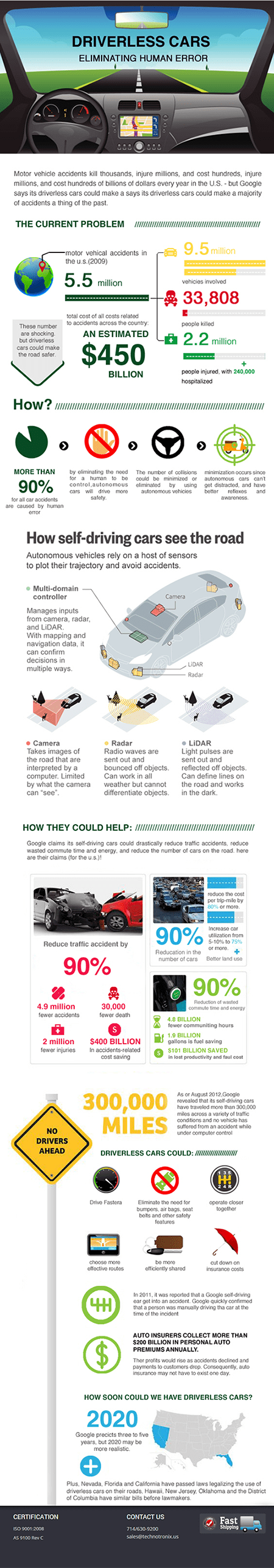

The so called intelligent car has highly advanced features that sound futuristic, but is one of a kind in current times. A relinquishing vehicle control with automatic cruise control, self breaking, automatic accident avoidance system, self parking, computerized steering and electronic engine control had broken the bar of Digitalized automotive innovation. Also a notion of driverless cars is the next predicted series of exciting transformation. Well! On the other hand, further modification is seen in the alternative powered vehicle, safety system, navigation and ergonomic vehicle set new trends in the market. The long range battery powered cars in the USA is one of the echo friendly models of innovation having multiple functionalities to get a user friendly experience. Going green and target the green thinking consumers, hydrogen powered car are also gearing up in California, Japan and Germany. The new in-vehicle standard includes embedded wireless connectivity, parallel parking system and head up display screen to catch the constant focus of the driver. All these innovations also have to go through various testing system like crashing test, durability test and many more to get a top model in the automotive market.

The other automotive PCB board application includes DC/AC power converter, Digital Display, Audio and Video equipment, Anti lock brake system, Electronic Computer Unit (ECU), Automatic dimming and electronic mirror control system, interior LED lighting, Power relay, engine timing system and remote diagnostic system. These automotive applications also hunt for the new concepts in PCB engineering that can raise the bar of the vehicle production to the next level.

Thus, the use of the printed circuit board is driving the automotive market in the fast moving world of technology, making the traditional vehicle pretty transparent and bringing new innovation every other day.

TechnoTronix is an ISO 9001-2015 certified with having 4 decades of experience in PCB manufacturing and PCB prototyping. Offering range of PCB customization to the automaker and suppliers, we have experience in PCB Making, co-engineering the PCB, rigorous testing system and on time order delivery process. In case if you have any questions, please feel free to contact us via email at sales@technotronix.us